The last automation frontier

Wiring harnesses are found in just about every modern device. Some are incredibly complex. A modern car wiring might have more than 3000m of wire and hundreds of components. Amazingly though these harnesses are largely hand made. The productivity, cost and quality benefits of automation have bypassed this industry, and the hunt for affordable skilled labour in massive numbers have led manufacturers to locations ever more remote. Factory in a box Q5D’s robots make complete wiring harnesses or looms - [...]

Freedom of design – the biggest reason to automate wire harness assembly?

Of the many reasons to automate wire harness assembly might surprise. No two wire harnesses are ever quite the same. That isn’t very surprising given the largely hand-made nature of wire harnesses, but the inevitable small variations add up to some big tolerances. Designers trying to accommodate the ever increasing need for more wiring to support greater functionality or electrification find themselves arguing over sub-millimetre amounts of space with the electrical team. Automation of wire harness assembly, and integration [...]

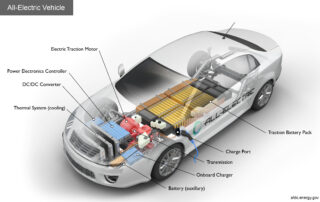

Electric vehicle makers race to automate wire harnesses

In the electric vehicle (EV) market, global competition is fierce, as demonstrated by recent price falls from leading players. Manufacturers are seeking cost and performance advantages over competitors. A vehicle’s wiring harness, which connects all the electrical and electronic circuits, is one of the largest and heaviest components bought by EV makers. It is also the last major barrier to fully automated manufacturing and all the benefits it could bring. Here’s why the issue is being addressed so urgently and [...]

Electrical Wire Processing Technology Expo (EWPTE) 2024 – Review

Electrical Wire Processing Technology Expo (EWPTE) is an annual trade show and conference in Milwaukee USA which specialises in wiring harness production and supply. https://www.electricalwireshow.com/ Q5D exhibited at this show for the first time in May 2024. Over the course of the 3 day conference and 2 day trade show we enjoyed the opportunity to share our unique approach to harness production in an event dedicated entirely to wire harnesses. The town of Milwaukee and the facilities were very [...]

Chris Elsworthy shortlisted for ‘Engineering Innovator of the Year’ Award

Q5D's CTO Director and Founder, Chris Elsworthy, has been shortlisted for the 'Engineering Innovator of the Year' award by the judges of the Engineering and Manufacturing Awards event. The award celebrates individuals or teams who can demonstrate how their initiative and ingenuity have resulted in extraordinary outcomes for their company and for society at large. Chris' work leading the design and development of the world's first additive manufacturing robot for wire harness automation is recognised by being shortlisted for the [...]

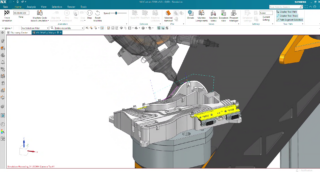

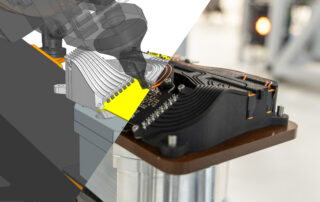

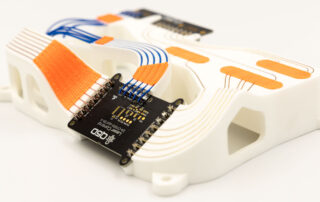

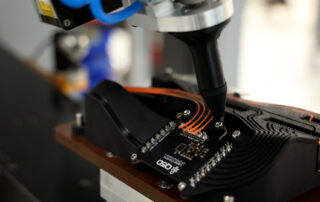

How a wiring robot came to solve the electrical function integration challenge

An interview with Chris Elsworthy, Q5D’s CTO. Q5D launched its first 5-axis CNC additive manufacturing robot cell, the CY1000 in 2023. Designed to automate the difficult task of adding electrical connections to increasingly complex products, the self-contained CY1000 robot eliminates the need for expensive, bulky, and heavy wiring harnesses. Freelance technical writer and journalist, Robert Huntley caught up with Chris Elsworthy, Chief Technology Officer at Q5D’s Bristol, UK headquarters to talk about the company’s vision and some of the [...]

Lockheed Martin leads 3 million USD investment round in Q5D to make tooling to automate wiring harness manufacture.

Bristol, UK, 12 April 2024: Q5D Technology, a company specializing in hardware and software tools for automating wiring harness manufacture, announced today the successful closure of a $3 million investment round, led by Lockheed Martin Ventures, the venture investment arm of Lockheed Martin Corporate, a global aerospace and defense company. Q5D has developed robotic tools combined with sophisticated computer-aided design and manufacturing software, enabling the autonomous addition of wiring and printed electronics directly onto product surfaces. This automation offers not [...]

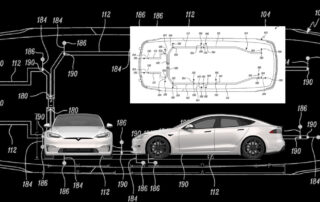

Why Tesla’s wiring patent points to something important for the whole industry.

Tesla's patent points at how they are thinking about some of the problems facing automakers generally. Tesla’s patent demonstrates their focus on simplifying the wiring harness, which helps with weight and cost reduction. However, on its own it may not be enough to address tone of the biggest questions facing the automotive industry today, which is "Who will build the wiring harnesses?" Finding the answer to this question was why Q5D was created. Our vision is to automate wire harness [...]

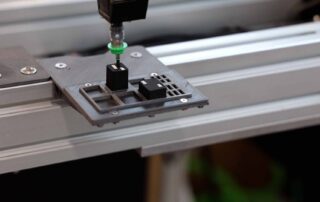

Q5D opens Technical Assessment Centre to help customers implement wiring automation

Bristol, 14th March 2024 – Q5D, a manufacturer of robots for wiring automation, has opened a customer Technical Assessment Centre (TAC) at its Portishead, Bristol, UK facility. The TAC is designed to help customers with feasibility studies, design for manufacturing, and prototyping as they transition from traditional wire harnesses to full automation. It has already attracted several major automotive OEMs and Tier 1 suppliers into that sector, some with projects running into 2025. Q5D’s CY1000 robot cell automates the addition of electrical wiring [...]

Four reasons why automating wiring harness production is critical to electrification

Electrification is a critical trend in the quest for a net zero economy. This process is accelerating, encompassing everything from transport to buildings, and industry. Wiring harnesses – the component enabling the transmission of power and data – are critical to this transition. Here Chris Elsworthy, Chief Technology Officer at Q5D, explains why automating the production of wire harnesses is essential to meet the growing industry demand. 1. There’s no electrification without wiring Buzzwords like “electrification”, “e-mobility” and “electric vehicles” [...]

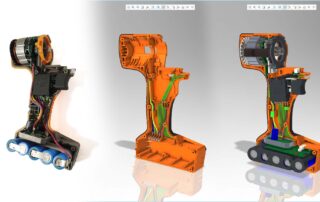

Q5D shortlisted for ‘Start-up of the Year’ in the Elektra Awards for developing a robot that automates the integration of wiring into electrical products

Bristol, 10th October 2023 – Q5D has developed a robot to automate the addition of wiring and printed electronics to products, eliminating the need for wire harnesses. The company’s work has now been recognised by Electronics Weekly’s Elektra Awards judges, where the company has been selected as a ‘Start-up of the Year’ finalist. The wiring in many electrical and electronic products is currently made and installed by hand. Over the last few years, Q5D, has developed a unique additive manufacturing process that [...]

How automation will shape the future of the wire harness industry

The wiring harness industry is experiencing rapid change due to the technological advances of electrification, the Internet of Things (IoT), and Industry 4.0. Increased functionality means a higher demand for power and data connections in modern appliances, products, and vehicles. As a result, the wire harness market is growing rapidly. Transparency Market Research forecasts a wire harness market of $200 billion by 2031. The productivity of wiring harness manufacturing is a critical issue. The challenge caused by electrification Historical wire [...]

The role of automation in raising UK productivity …

Q5D is delighted to be sponsoring an event in conjunction with AMRC and the Bessemer Society Numbers are limited to ensure there is time for networking and the tours of Factory 2050. You can book your ticket with the Bessemer Society HERE...

Getting to Net-Zero

One of the questions we are often asked is about how our technology can meet the challenges of the future. One of the biggest of these of course is Net-Zero. Looking at some of the case studies we have tackled in the creation of our new approach to wiring has allowed us to estimate our impact on this critical need.

The content dilema

Function v weight & space Wiring harnesses are critical components in many of the products we rely on, from cars and planes to white goods and consumer electronics, enabling electrical functions such as lighting, electric motors, and sensors. Wire harnesses therefore play a key role in electrification, the Internet of Things (IoT), and Industry 4.0 and the benefits brought by these developments fuel an ever increasing demand for more and more wiring. Customer expectations and the impact of [...]

Mass customisation

Mass customization is that ideal world where the customer can enjoy a personalized product, whilst the manufacturer retains the advantages and low unit costs of mass produced items. Just-in-time (JIT) manufacturing has often been adopted as a means of achieving mass customization, with varying degrees of success for both the customer and the manufacturer. One of the consequences of JIT manufacturing is the reliance on the supply chain. Products that need electrics in order to function - and that's most [...]

How automation will shape the future of the wire harness industry

The wiring harness industry is experiencing rapid increase in demand due to factors such as electrification, the Internet of Things (IoT), and Industry 4.0. All these drive a need for increased functionality, which means a higher demand for power and data connections in modern appliances, products, and vehicles. As a result, the wire harness market is growing rapidly. Transparency Market Research forecasts a wire harness market of $200 billion by 2031. Productivity of wiring harness manufacture is a critical issue. [...]

Why does wiring automation matter?

Wiring harnesses are critical components in many of the products we rely on, from cars and planes to white goods and consumer electronics, enabling electrical functions such as lighting, electric motors, and sensors. As such, wire harnesses play a key role in electrification, the Internet of Things (IoT), and Industry 4.0. In this blog, we will look at why automating the production of wiring harnesses – presently a labour-intensive process – is so critical and how it can act [...]

Revolutionising Printed Electronics

Cheaper, better, printed electronics on any surface! Q5D Technology is excited to be starting a new project, Prime3D, which aims to revolutionise the way that printed electronics are done: dramatically improving the performance and expanding the range of substrate materials whilst also reducing cost. Current technologies like Laser Direct Structuring (LDS) are used to make plastics parts with very high quality copper tracks for use in: antennas, switches, connectors and sensors. It is predicted there will be a market size [...]