Manufacturing seats and cabin interiors for commercial aircraft is highly labour intensive. The range of customisation required from airline customers and the variation in seat dependent on both aircraft type and position of seat within the fuselage, means that seats have to be made by hand because of the very low batch numbers.

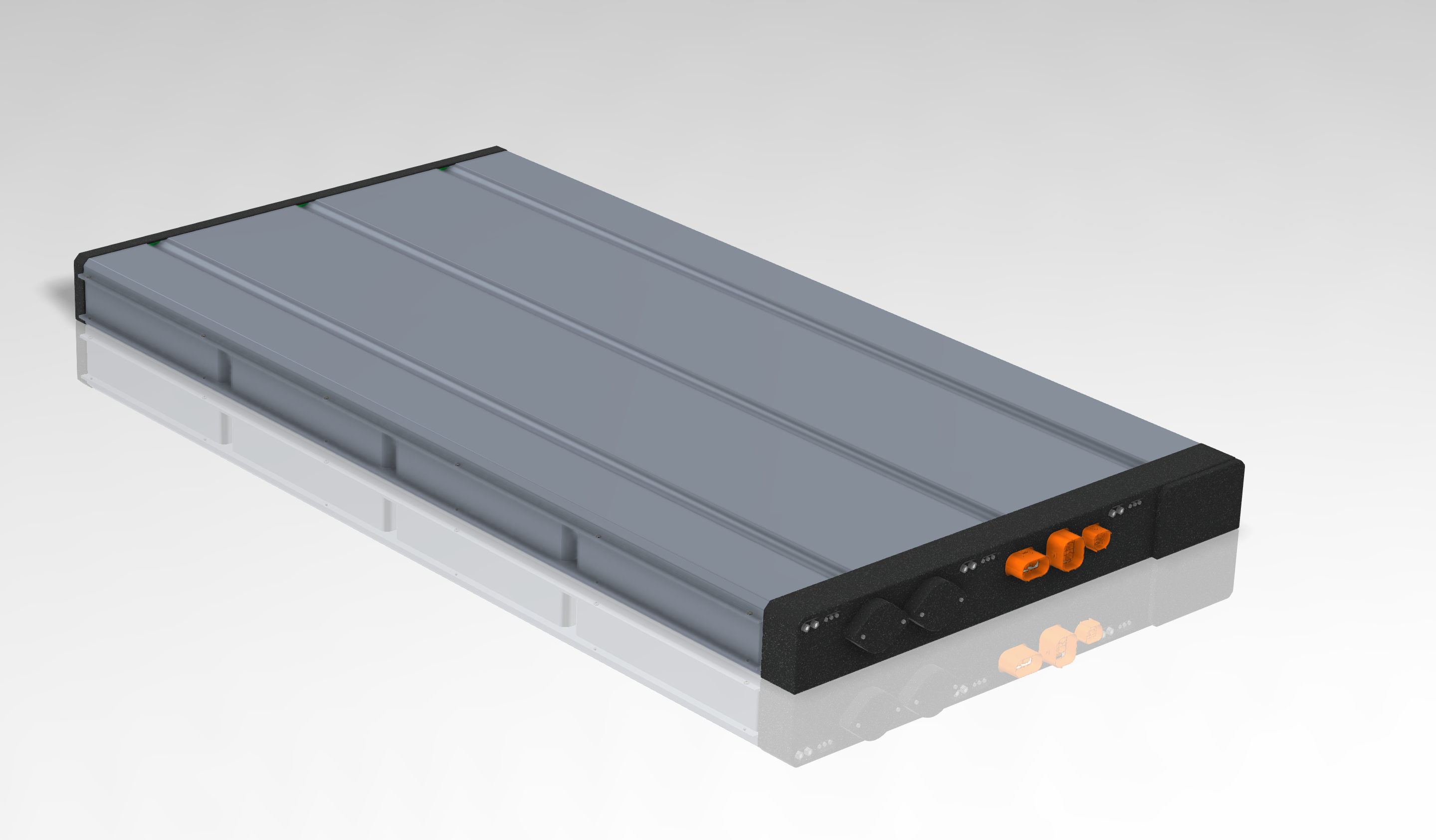

Q5D was asked to evaluate a redesign of one product (a stowage box) and were given four key aims:

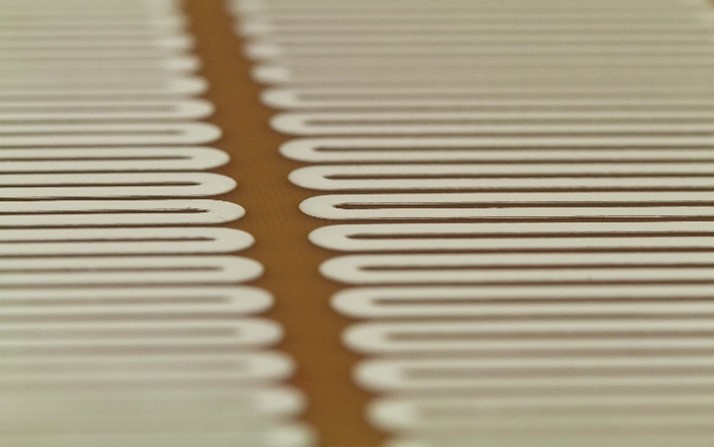

- Use a standard blow moulded polymer core and add stiffening and customisation features using 3D 5-axis polymer additive process

- Automate the addition of wiring and terminations

- Remove weight and improve functionality

- Ensure that the unit can be line replaceable within 15 minutes

Material requirements for aircraft cabins are stringent. Smoke, fire and toxicity regulations mean that interiors of aircraft are often made from materials such as Kydex which is not normally associated with additive manufacturing. Q5D has uniquely developed and patented methods for printing Kydex and overprinting onto Kydex parts.

One additional benefit of automating the addition of wiring to these stowage units is a 5 kg saving in weight, per seat because the metal cable management system normally used to secure the wiring harness is not required.

Benefits

- Automation of wiring addition

- Supports high product variability

- Saves weight

- Reduces space used by wiring

- Increases productivity

- Reduced takt time

Ready to see this in action?

Contact us to discuss your project.