Q5D has the only process capability that can work at large scale on aerospace components.

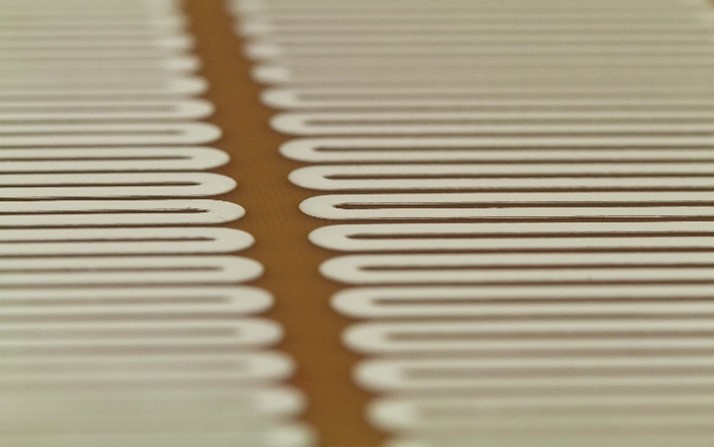

Frequency selective shielding has many applications from cleaning hand-held or wi-fi signals to stealth technology. The shielding is made using a conductor patterned with a repeating motif. Multiple layers may be stacked in in order to improve performance.

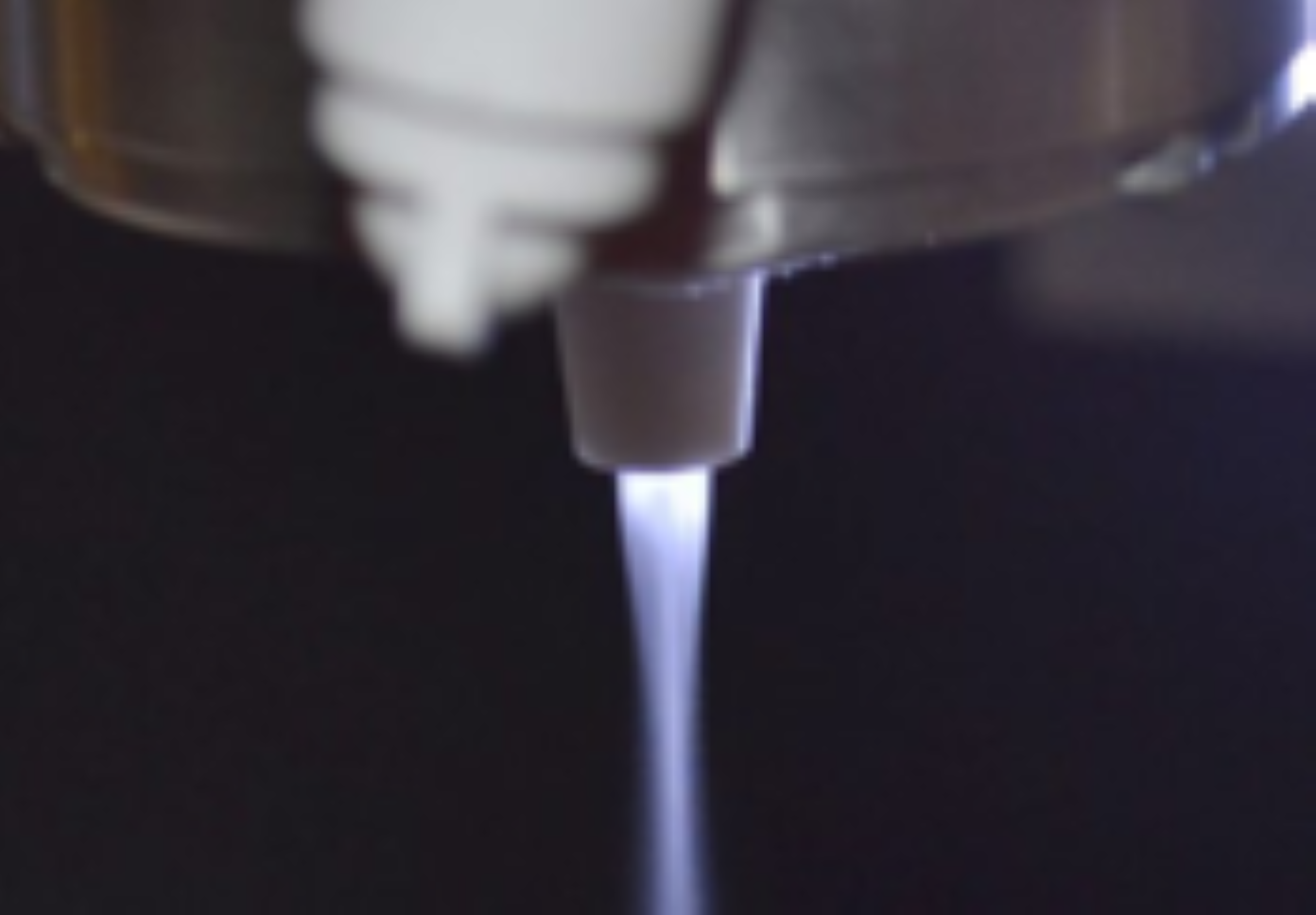

Current methods of manufacturing use metal foils or printed electronics. Laser Direct Structuring (LDS) is one such technique, but is requires highly expensive materials loaded with nano-particles and plating in an electrodeless bath. This produces high quality parts, but there are limitations on the size of the part that can be produced, and the range of polymers available with nano-particles is small. Aerospace polymers are not available for LDS.

Q5D has successfully demonstrated the ability to produce test parts using laser sintering which passed the required tests. Development work to produce the same effect on curved surfaces is continuing.

The success of this project unlocks the cost effective production of parts using aerospace polymer substrates and complex surfaces up to 1m across, 3x current methods.

Benefits

- Complex and internal curved shapes

- Multiple layers

- Precise register / offset between layers

- Enables new product options

Ready to see this in action?

Contact us to discuss your project.