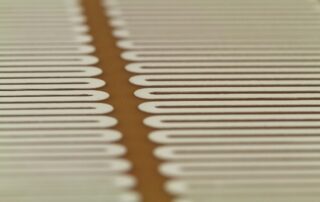

Frequency Selective Shielding

Q5D has the only process capability that can work at large scale on aerospace components. Frequency selective shielding has many applications from cleaning hand-held or wi-fi signals to stealth technology. The shielding is made using a conductor patterned with a repeating motif. Multiple layers may be stacked in in order to improve performance. Current methods of manufacturing use metal foils or printed electronics. Laser Direct Structuring (LDS) is one such technique, but is requires highly expensive materials loaded with [...]

Aircraft Interior

Manufacturing seats and cabin interiors for commercial aircraft is highly labour intensive. The range of customisation required from airline customers and the variation in seat dependent on both aircraft type and position of seat within the fuselage, means that seats have to be made by hand because of the very low batch numbers. Q5D was asked to evaluate a redesign of one product (a stowage box) and were given four key aims: Use a standard blow moulded polymer core [...]

Embedded Heating

This aerospace customer wanted to investigate methods to create heating tracks on complex composite surfaces. Many aircraft surfaces need to be heated to prevent the formation of ice which can change the aerodynamic properties of a part and in extreme instances cause instability of the aircraft. More and more aircraft components are made from non-metallic parts for strength and lightness, and these can be difficult to de-ice. Q5D was able to demonstrate a method of applying and curing silver [...]