We want all our customers to be able to enjoy the latest developments. We’re a young company, our technology is developing fast and we have lots of exciting plans. We believe Hardware as a Service (HaaS) is the best way to deliver the benefits of these developments to you.

HaaS delivers hardware, software and services necessary to deploy and support the manufacturing of your products for a monthly fee.

There are two HaaS categories of package:

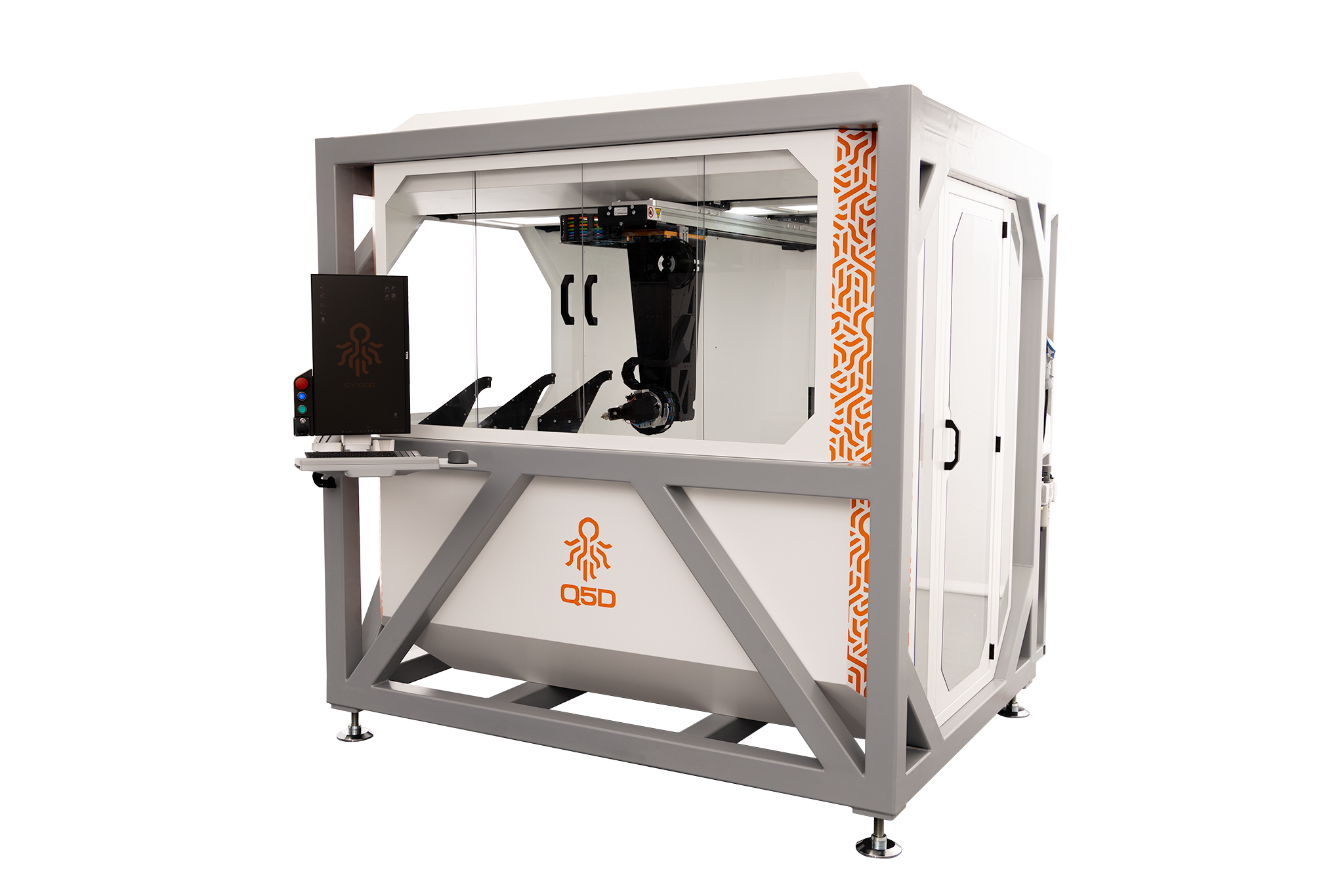

- Wired5D focused on the automation of adding wires to complex products

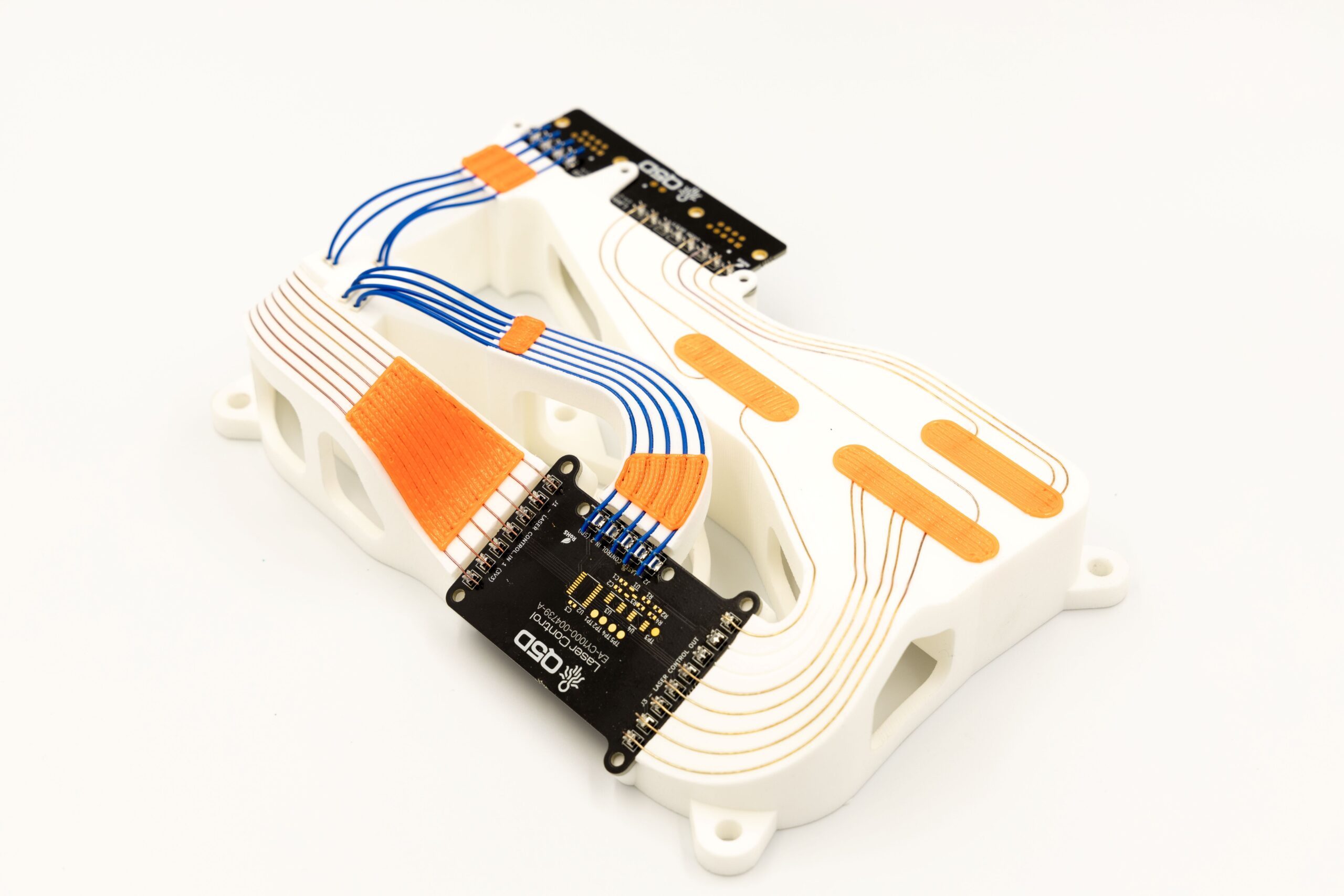

- Circuit5D focused on the addition of printed circuits to non-planar surfaces

Every package is tailored to your precise needs based on the elements listed below.

Wire5D

Circuit5D