Q5D wins £918,169 ‘Made Smarter Innovation’ grant from Innovate UK for collaborative software development for wiring harness automation robot

Q5D wins £918,169 ‘Made Smarter Innovation’ grant from Innovate UK for collaborative software development for wiring harness automation robot

Ready to see Q5D in action?

Contact us to discuss your project.

Bristol, 5th March 2024 – Q5D, a manufacturer of wire harness automation equipment for additive manufacturing, has secured £918,169 in grant funding for the company and its partners to further develop the software that drives the CY1000 wiring automation robot announced earlier this year. The grant is shared with its partners in the project, the Manufacturing Technology Centre, an independent research and technology organisation, and Emixa, a digital transformation specialist and the leading Siemens Partner in Europe.

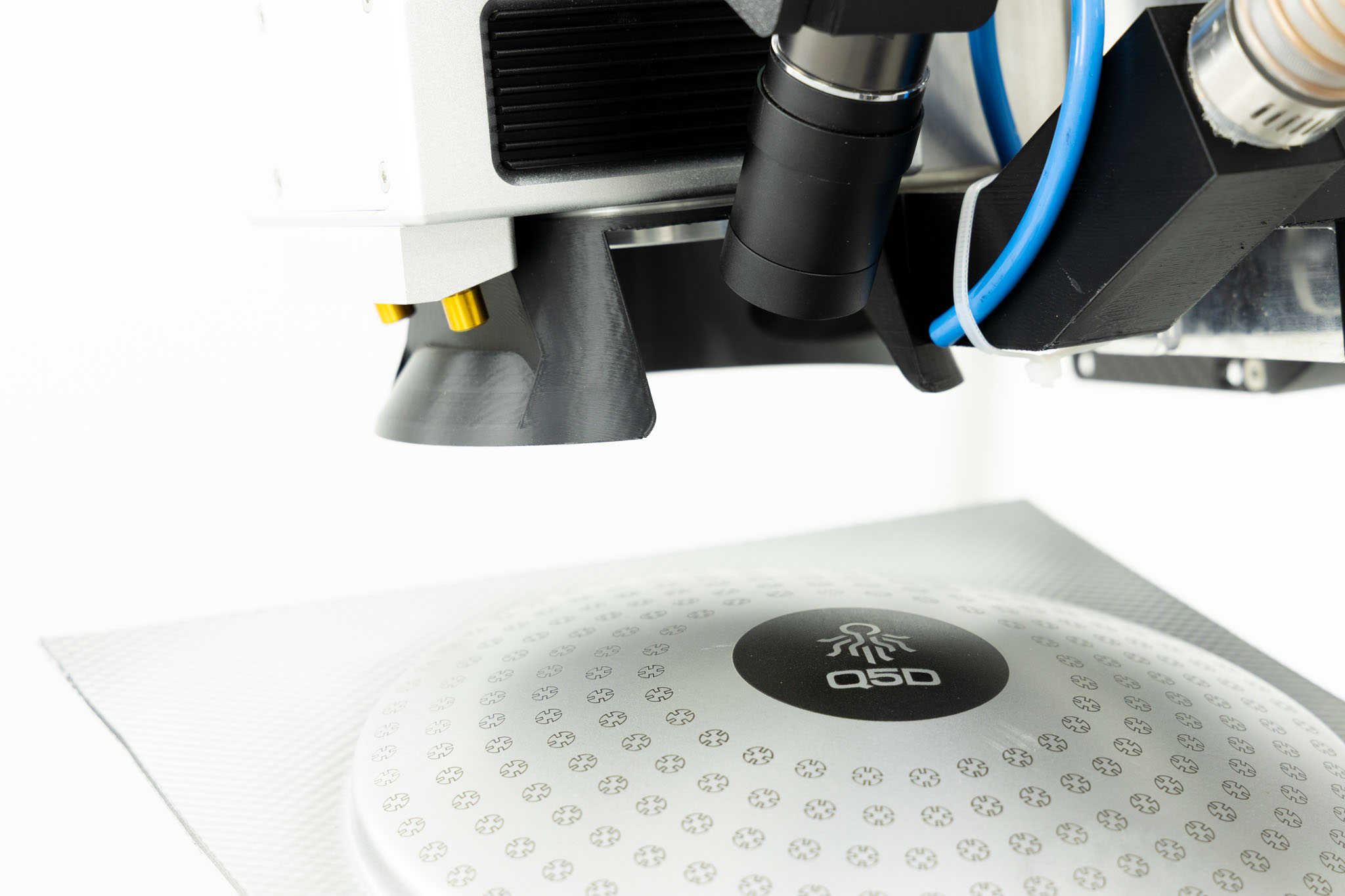

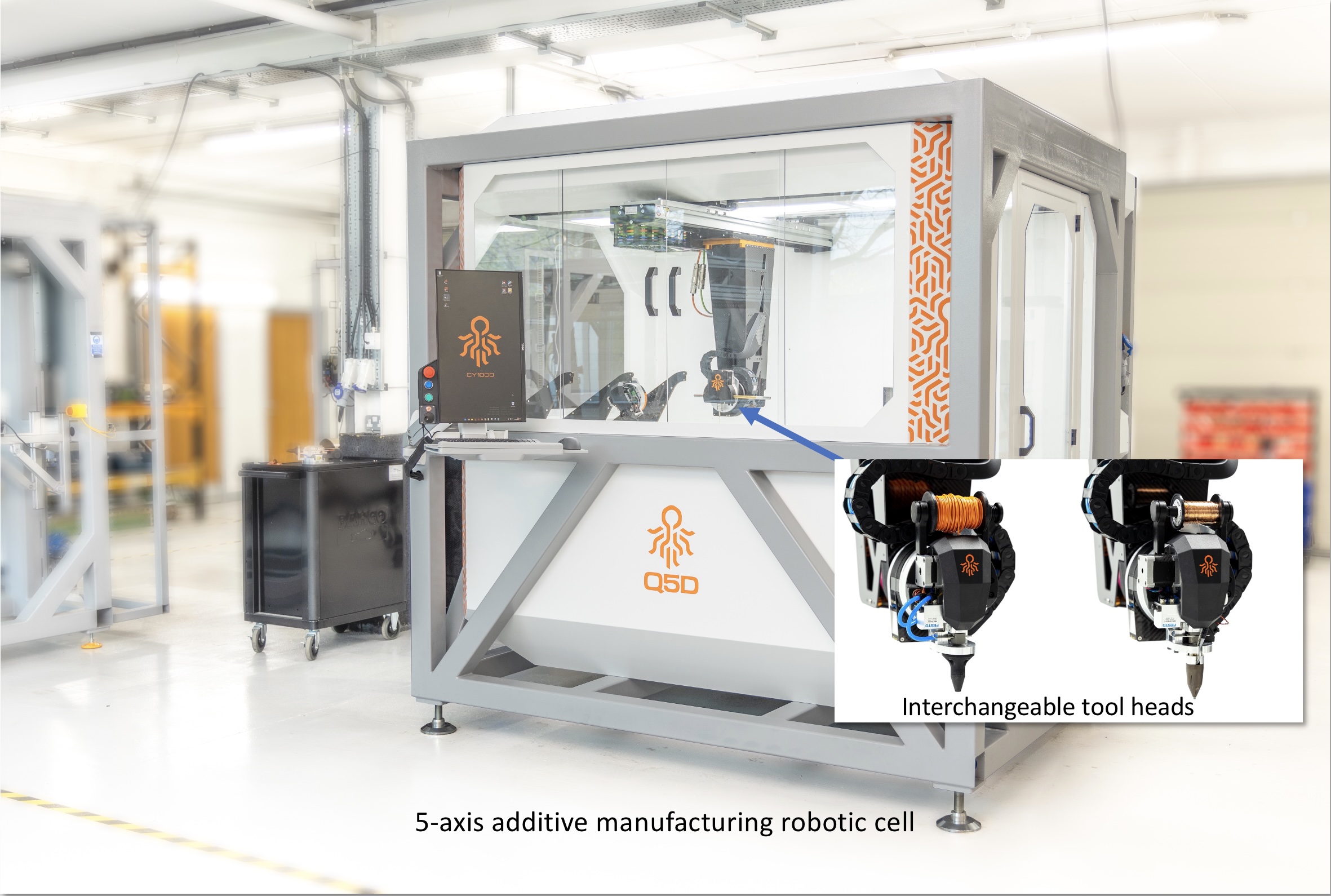

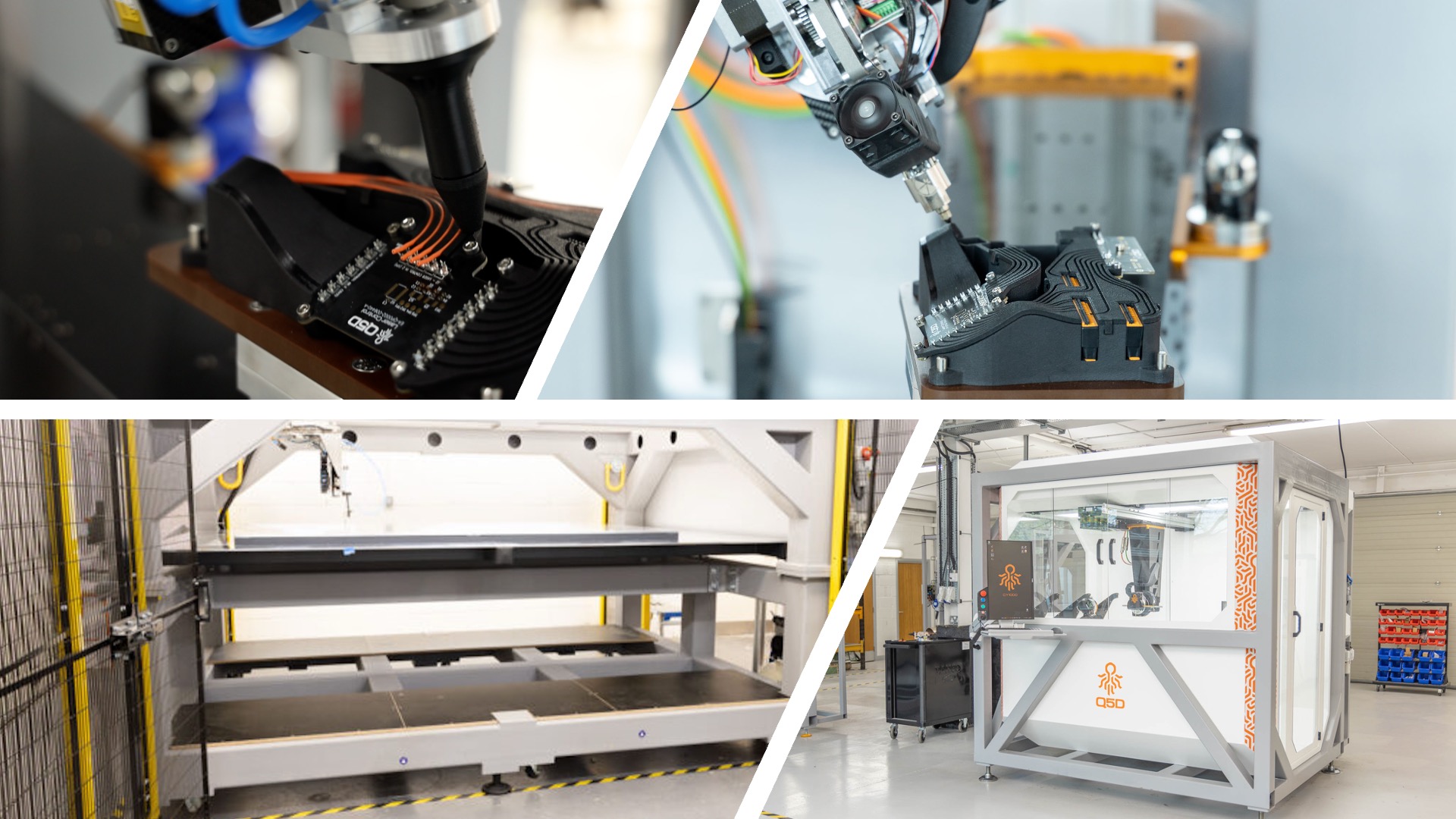

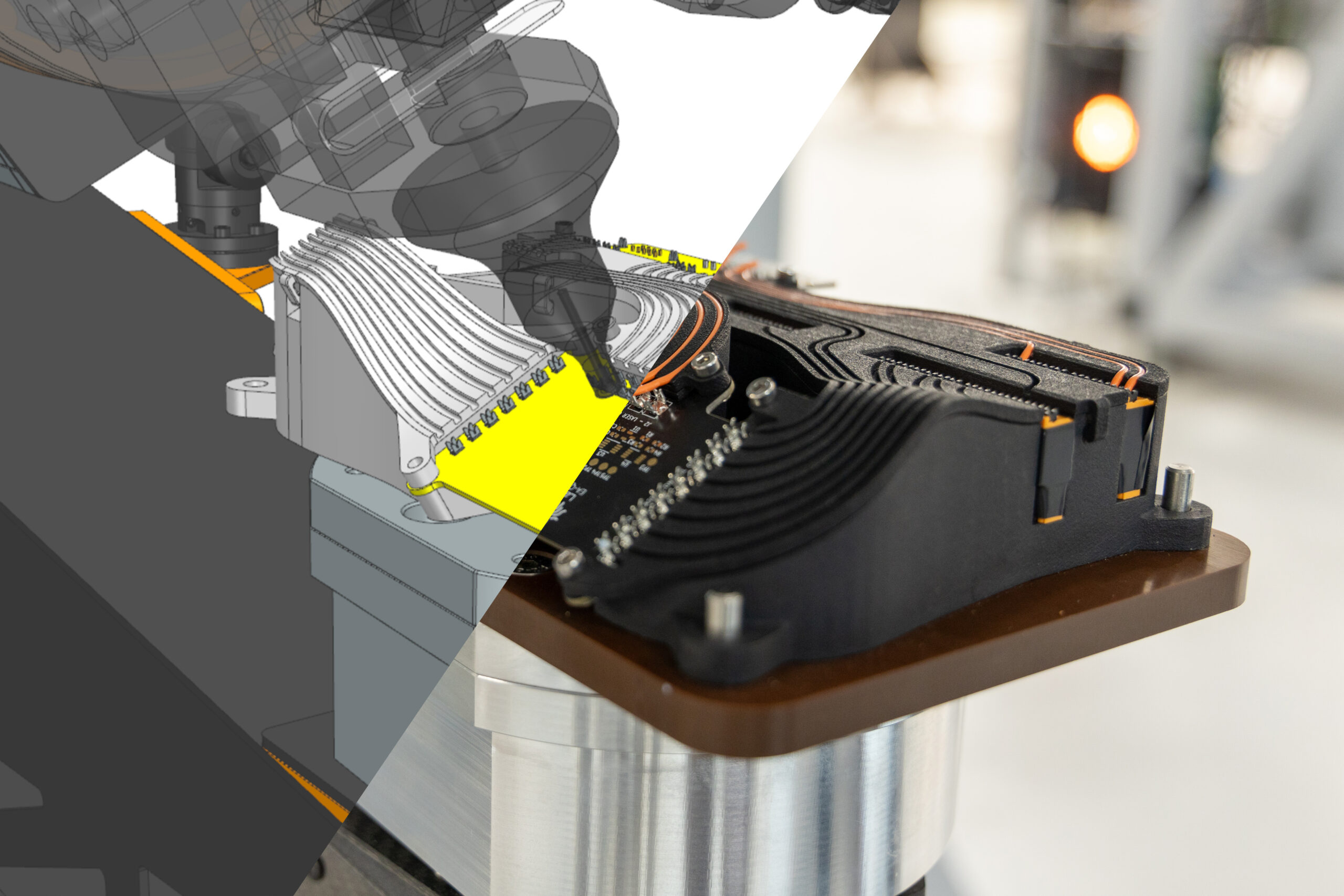

The CY1000 5-axis CNC robotic handling cell automates the addition of electrical wiring and terminations in products, delivering 5X to 10X productivity improvements. Its unique ‘Electrical Function Integration’ technology mitigates the need for expensive, heavy, and potentially unreliable wiring harnesses, offers greater flexibility to product designers, and reduces both manufacturing and supply chain costs and risks. The machine also offers precision polymer deposition and deposition of conductive inks. All of this can be done on complex-shaped surfaces.

Such complex functionality requires sophisticated software for optimum performance. The grant will fund the next stage of software development. There are three linked layers of software required: Machine control, User Interface (UI), and CAD/CAM. The machine control and UI are developed in-house by Q5D. Post processors to the Siemens NX CAD/CAM software have been written by Emixa to create a digital twin of the hardware and create the machine code needed to control it from CAD designs.

The software is currently functional and experienced CAD/CAM engineers can use it. However, the workflow from design to manufacture requires simplification, and the interfaces need to be made more accessible before they can be used by non-expert customers.

This project focuses on the further development of the software to the point where it can be successfully deployed at the Manufacturing Technology Centre and work on projects for end-user companies. It runs until 31 December 2024.