Q5D to double technical assessment centre capacity as demand for wiring automation soars

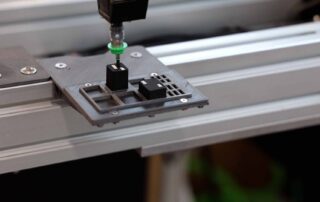

Bristol, UK, July 1, 2025: Q5D, a manufacturer of robotic cells that automate product electrification, is doubling the resources at its Technical Assessment Centre (TAC) in Bristol, UK. The TAC is used by customers for feasibility studies and prototyping for embedding wiring directly into the structure of a products, rather than using separate wire harnesses. The patented process, which uses a 5-axis manufacturing robot, is particularly in demand in the automotive and aerospace industries and the three machines currently available [...]

Q5D secures $13.5 million in funding for wiring automation, including Series A venture round led by Lockheed Martin

Bristol, UK, June 10, 2025: Q5D has raised 13.5 million USD in funding to advance its robotic cells that automate product electrification, bringing its total funding to 16.7 million USD. This new funding includes a 2.6 million USD grant (2.0 million GBP) from Innovate UK and a 10.9 million USD Series A co-led by existing investors, Lockheed Martin Ventures, Chrysalix and Maven SWIF, with other investment from SOSV, UKI2S, UntroD and CPI Enterprises. Q5D is tackling one of the [...]

Q5D to debut the world’s first wiring harness automation robot to take 200 USD off the cost of a car

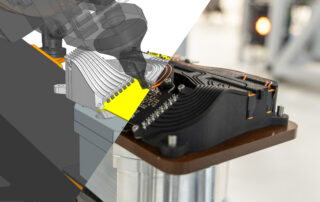

Bristol, UK, 28, March, 2025: Q5D Technology, pioneers of hardware and software tools for robotic wiring harness manufacture, has taken delivery of the core structure of frame and drives for its latest and largest to date wire harness automation robot at its Bristol headquarters in the UK. The frame of the robotic cell will undergo final assembly and be ready for service as the world’s most comprehensive wire harness automation robot, dubbed the SQ25W, in the late spring this year. The [...]

Q5D picks up the Manufacturing Innovation prize at the Robotics and Automation Awards

Chris Elsworthy, CTO, and Simon Baggott, CMO, received the Manufacturing Innovation award at the Robotics and Automation Awards ceremony in London last night (6th November). A prestigious panel of judges selected the CY1000 wiring automation robot as a technology that "exemplified the power of technology to transform businesses, improve efficiency and create new possibilities for growth in diverse fields." It's another significant endorsement of Q5Ds technology and its potential to transform wiring harness cost, weight, durability and electrical performance.

Q5D Technologies Appoints Pragmatic Semiconductor’s Scott White as Chair

Bristol, UK, 16 August 2024: Q5D Technologies has named Scott White as Chair of the Board. Q5D is a robotics and software company that automates the manufacture of wiring harnesses, one of the last parts of the manufacturing process that is still done by hand. This strategic appointment marks a significant milestone in Q5D’s growth as the company leverages its robotic cell technology to transform manufacturing in global sectors such as automotive and aerospace. Scott White is an accomplished serial [...]

Q5D Technologies Shortlisted for Robotics and Automation Awards for Wire Harness Innovation

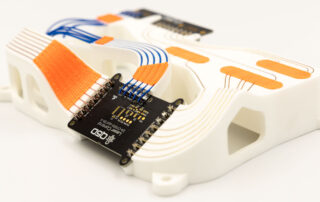

Bristol, UK, 6 August, 2024: Q5D Technologies Limited has been shortlisted in two categories for the Robotics and Automation Awards 2024. Q5D has earned recognition in the “Best New or Small Company” and “Manufacturing Innovation” categories, which celebrate innovative and disruptive forces within the sector, acknowledging Q5D’s contributions to transforming traditional wiring harness production. Q5D’s nominations are based on its CY1000, a 5-axis additive robotic manufacturing cell that automates the integration of wires, conductive tracks and electrical connectors directly [...]

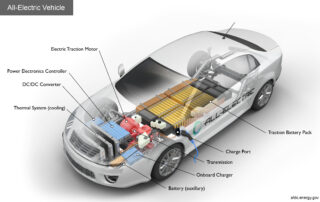

Electric vehicle makers race to automate wire harnesses

In the electric vehicle (EV) market, global competition is fierce, as demonstrated by recent price falls from leading players. Manufacturers are seeking cost and performance advantages over competitors. A vehicle’s wiring harness, which connects all the electrical and electronic circuits, is one of the largest and heaviest components bought by EV makers. It is also the last major barrier to fully automated manufacturing and all the benefits it could bring. Here’s why the issue is being addressed so urgently and how wire harness automation will make EVs more competitive in every way.

Chris Elsworthy shortlisted for ‘Engineering Innovator of the Year’ Award

Q5D's CTO Director and Founder, Chris Elsworthy, has been shortlisted for the 'Engineering Innovator of the Year' award by the judges of the Engineering and Manufacturing Awards event. The award celebrates individuals or teams who can demonstrate how their initiative and ingenuity have resulted in extraordinary outcomes for their company and for society at large. Chris' work leading the design and development of the world's first additive manufacturing robot for wire harness automation is recognised by being shortlisted for the [...]

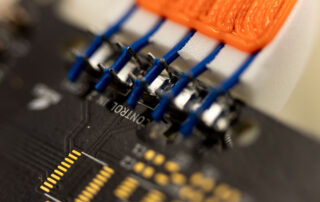

How a wiring robot came to solve the electrical function integration challenge

An interview with Chris Elsworthy, Q5D’s CTO. Q5D launched its first 5-axis CNC additive manufacturing robot cell, the CY1000 in 2023. Designed to automate the difficult task of adding electrical connections to increasingly complex products, the self-contained CY1000 robot eliminates the need for expensive, bulky, and heavy wiring harnesses. Freelance technical writer and journalist, Robert Huntley caught up with Chris Elsworthy, Chief Technology Officer at Q5D’s Bristol, UK headquarters to talk about the company’s vision and some of the [...]

Lockheed Martin leads 3 million USD investment round in Q5D to make tooling to automate wiring harness manufacture.

Bristol, UK, 12 April 2024: Q5D Technology, a company specializing in hardware and software tools for automating wiring harness manufacture, announced today the successful closure of a $3 million investment round, led by Lockheed Martin Ventures, the venture investment arm of Lockheed Martin Corporate, a global aerospace and defense company. Q5D has developed robotic tools combined with sophisticated computer-aided design and manufacturing software, enabling the autonomous addition of wiring and printed electronics directly onto product surfaces. This automation offers not [...]

Q5D opens Technical Assessment Centre to help customers implement wiring automation

Bristol, 14th March 2024 – Q5D, a manufacturer of robots for wiring automation, has opened a customer Technical Assessment Centre (TAC) at its Portishead, Bristol, UK facility. The TAC is designed to help customers with feasibility studies, design for manufacturing, and prototyping as they transition from traditional wire harnesses to full automation. It has already attracted several major automotive OEMs and Tier 1 suppliers into that sector, some with projects running into 2025. Q5D’s CY1000 robot cell automates the addition of electrical wiring [...]

Q5D wins £918,169 ‘Made Smarter Innovation’ grant from Innovate UK for collaborative software development for wiring harness automation robot

Bristol, 5th March 2024 – Q5D, a manufacturer of wire harness automation equipment for additive manufacturing, has secured £918,169 in grant funding for the company and its partners to further develop the software that drives the CY1000 wiring automation robot announced earlier this year. The grant is shared with its partners in the project, the Manufacturing Technology Centre, an independent research and technology organisation, and Emixa, a digital transformation specialist and the leading Siemens Partner in Europe. The CY1000 5-axis CNC robotic handling [...]

Four reasons why automating wiring harness production is critical to electrification

Electrification is a critical trend in the quest for a net zero economy. This process is accelerating, encompassing everything from transport to buildings, and industry. Wiring harnesses – the component enabling the transmission of power and data – are critical to this transition. Here Chris Elsworthy, Chief Technology Officer at Q5D, explains why automating the production of wire harnesses is essential to meet the growing industry demand. 1. There’s no electrification without wiring Buzzwords like “electrification”, “e-mobility” and “electric vehicles” [...]

IET Excellence and Innovation Awards recognise Q5D’s ground-breaking wiring robot

Bristol, 17th October 2023 – Q5D has been shortlisted as a finalist for the 2023 IET Excellence and Innovation Awards in the ‘AI and Robotics’ category. These prestigious awards recognise ground-breaking innovations and best practices in engineering, science, and technology. This year, the social and environmental impact of the competing technologies was a core consideration for the judges. The IET (Institute of Engineering and Technology), headquartered in London, is a professional engineering body representing more than 154,0000 engineering and technology professionals in 148 [...]

Q5D to show first public demonstration of wiring automation robot for eliminating manual harnesses at the Advanced Engineering show

Bristol, 11th October, 2023 - Q5D will give the first public demonstration of its CY1000, 5-axis additive manufacturing robotic cell on stand Q162 at the Advanced Engineering Show at the NEC from November 1st to 2nd, 2023. The CY1000 automates the addition of electrical wiring and connectors to increasingly complex products. Through the additive manufacturing process, called ‘Electrical Function Integration’, the robot mitigates the need for traditional wire harnesses, which are large, heavy, costly, and often unreliable. It integrates bare [...]

Q5D shortlisted for ‘Start-up of the Year’ in the Elektra Awards for developing a robot that automates the integration of wiring into electrical products

Bristol, 10th October 2023 – Q5D has developed a robot to automate the addition of wiring and printed electronics to products, eliminating the need for wire harnesses. The company’s work has now been recognised by Electronics Weekly’s Elektra Awards judges, where the company has been selected as a ‘Start-up of the Year’ finalist. The wiring in many electrical and electronic products is currently made and installed by hand. Over the last few years, Q5D, has developed a unique additive manufacturing process that [...]

How automation will shape the future of the wire harness industry

The wiring harness industry is experiencing rapid change due to the technological advances of electrification, the Internet of Things (IoT), and Industry 4.0. Increased functionality means a higher demand for power and data connections in modern appliances, products, and vehicles. As a result, the wire harness market is growing rapidly. Transparency Market Research forecasts a wire harness market of $200 billion by 2031. The productivity of wiring harness manufacturing is a critical issue. The challenge caused by electrification Historical wire [...]