Q5D Unveils Five-Axis Laser Metallisation System for High Precision 3D Electronics

Q5D Unveils Five-Axis Laser Metallisation System for High Precision 3D Electronics

Ready to see Q5D in action?

Contact us to discuss your project.

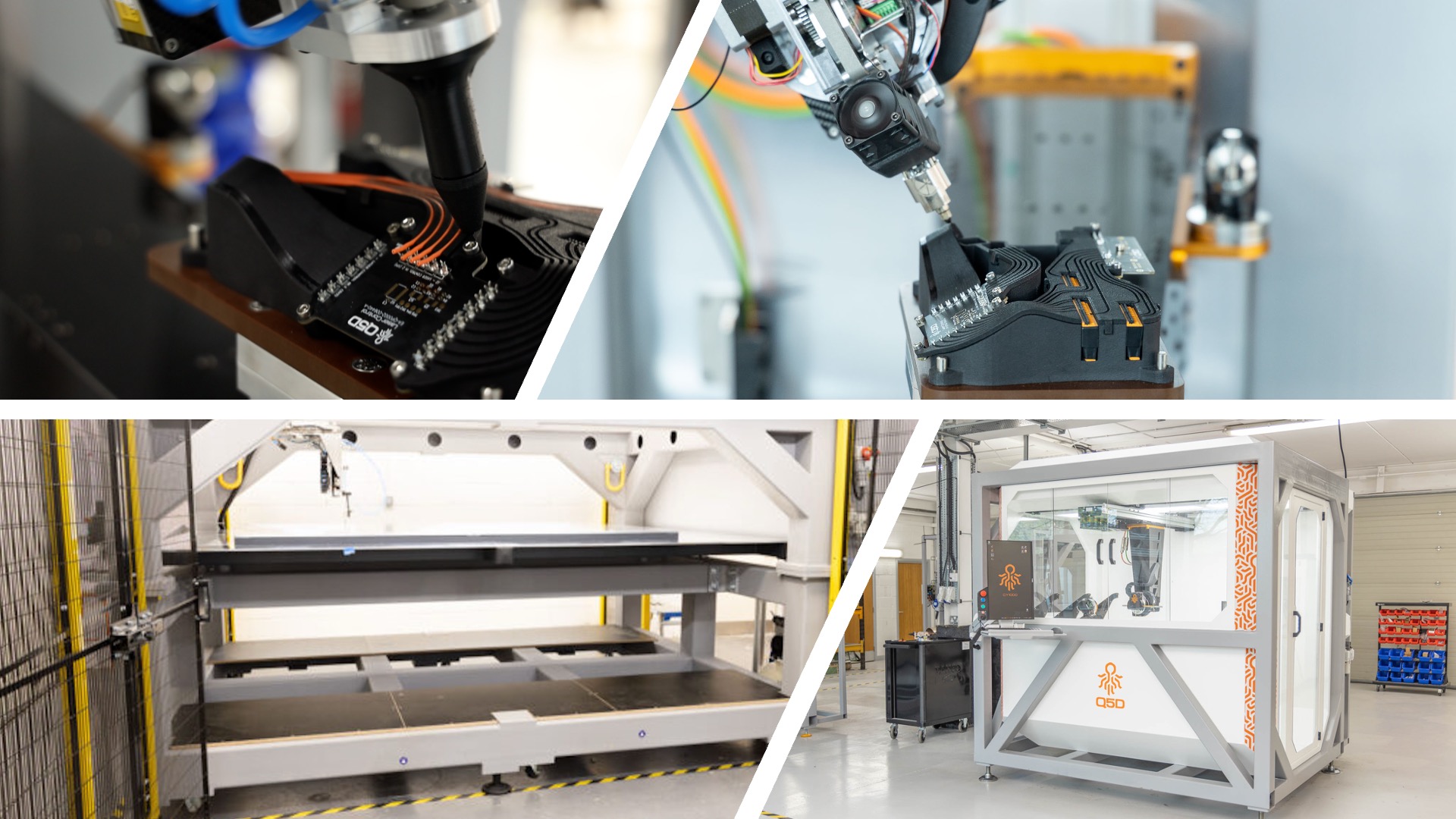

Bristol, UK, January 22, 2026: Q5D, a manufacturer of robotic cells for product electrification, has introduced a laser-assisted selective metallisation process that enables high-precision, high-speed creation of conductive tracks onto large, complex three-dimensional (3D) substrates. The substrates may be polymers or one of a wide range of other materials including ceramics and specialist aerospace dielectrics. The system delivers precision, speed, and flexibility in the manufacture of products such as wireless antennas, radio frequency selective shielding, capacitive touch elements and sensors.

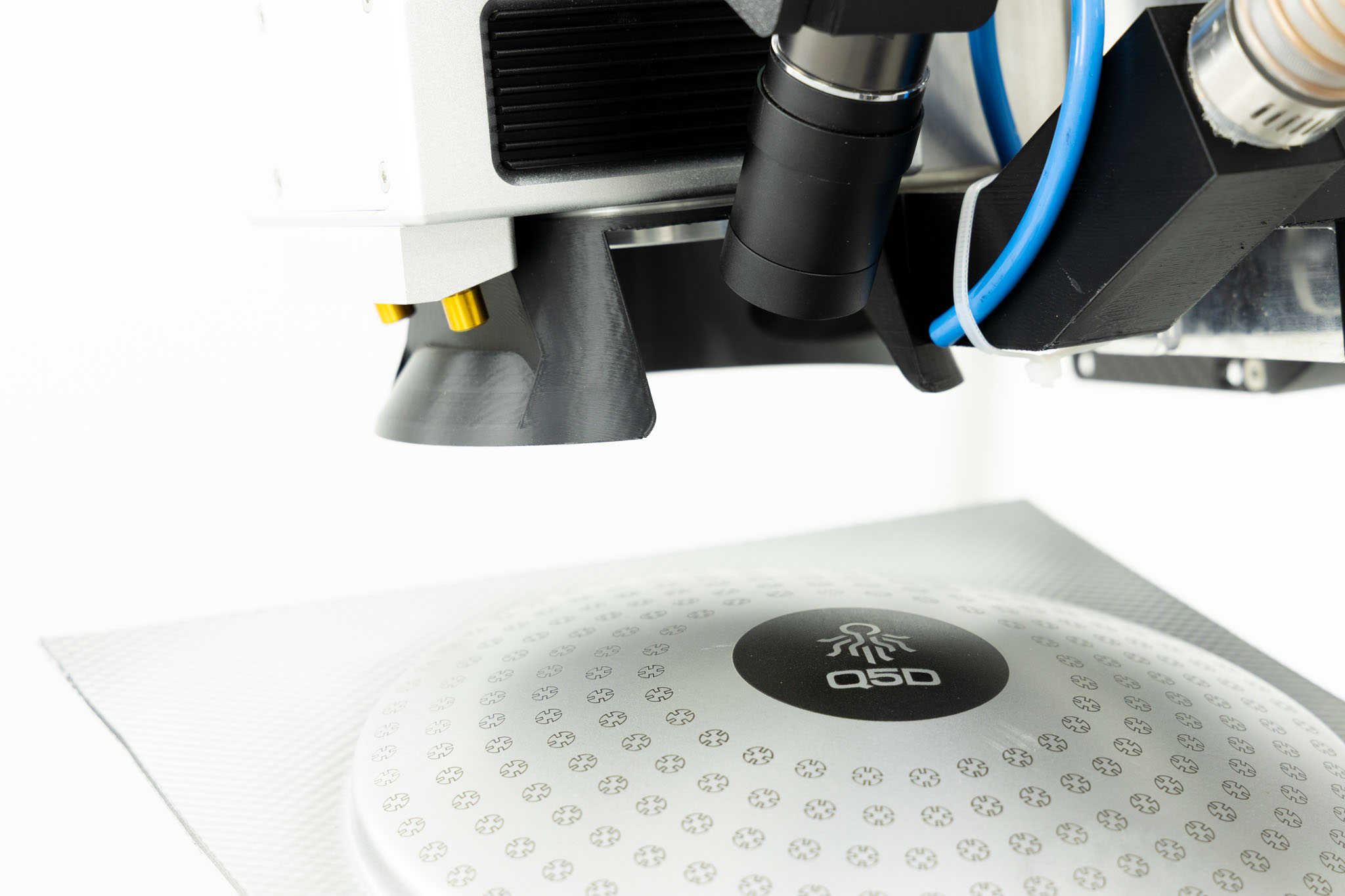

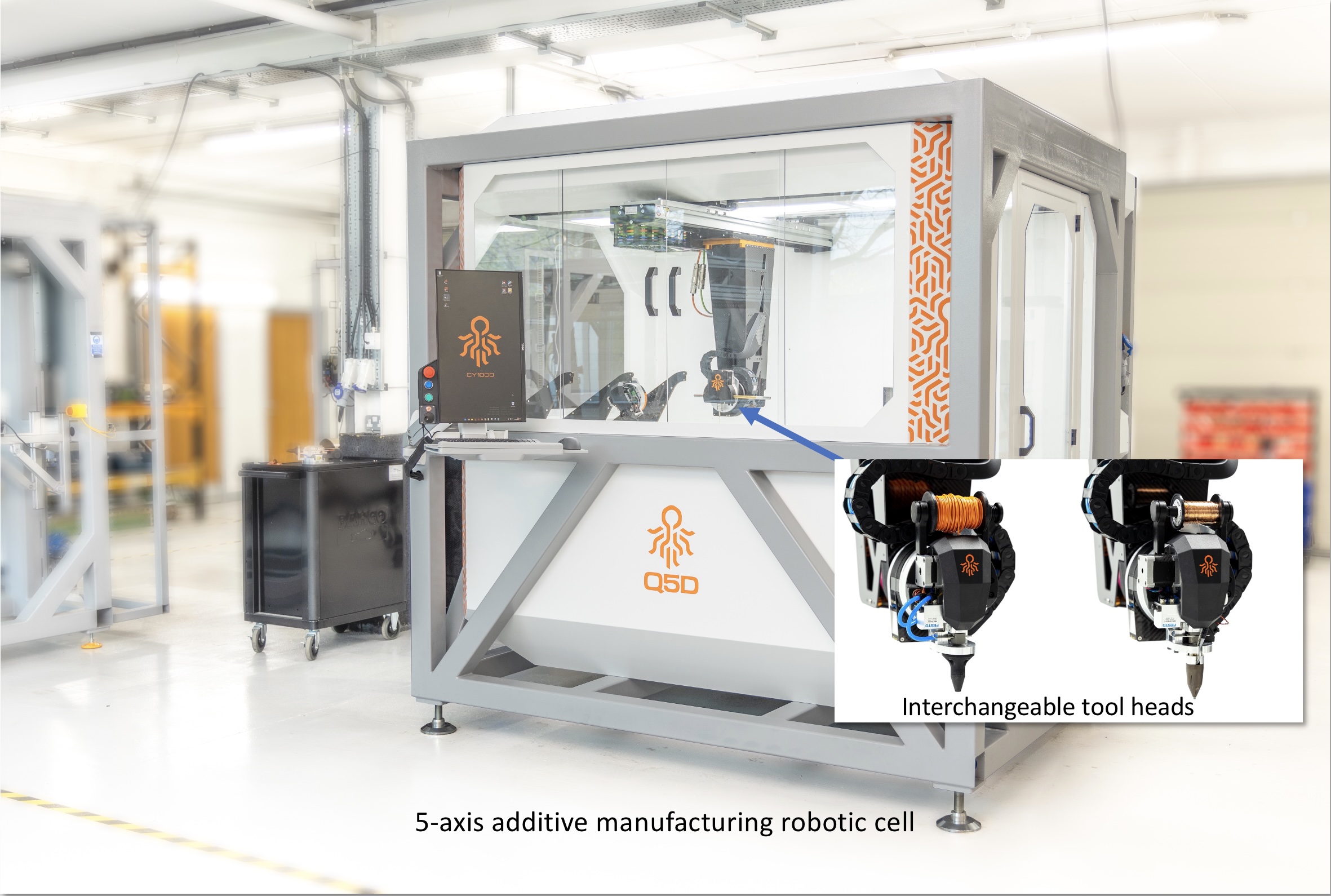

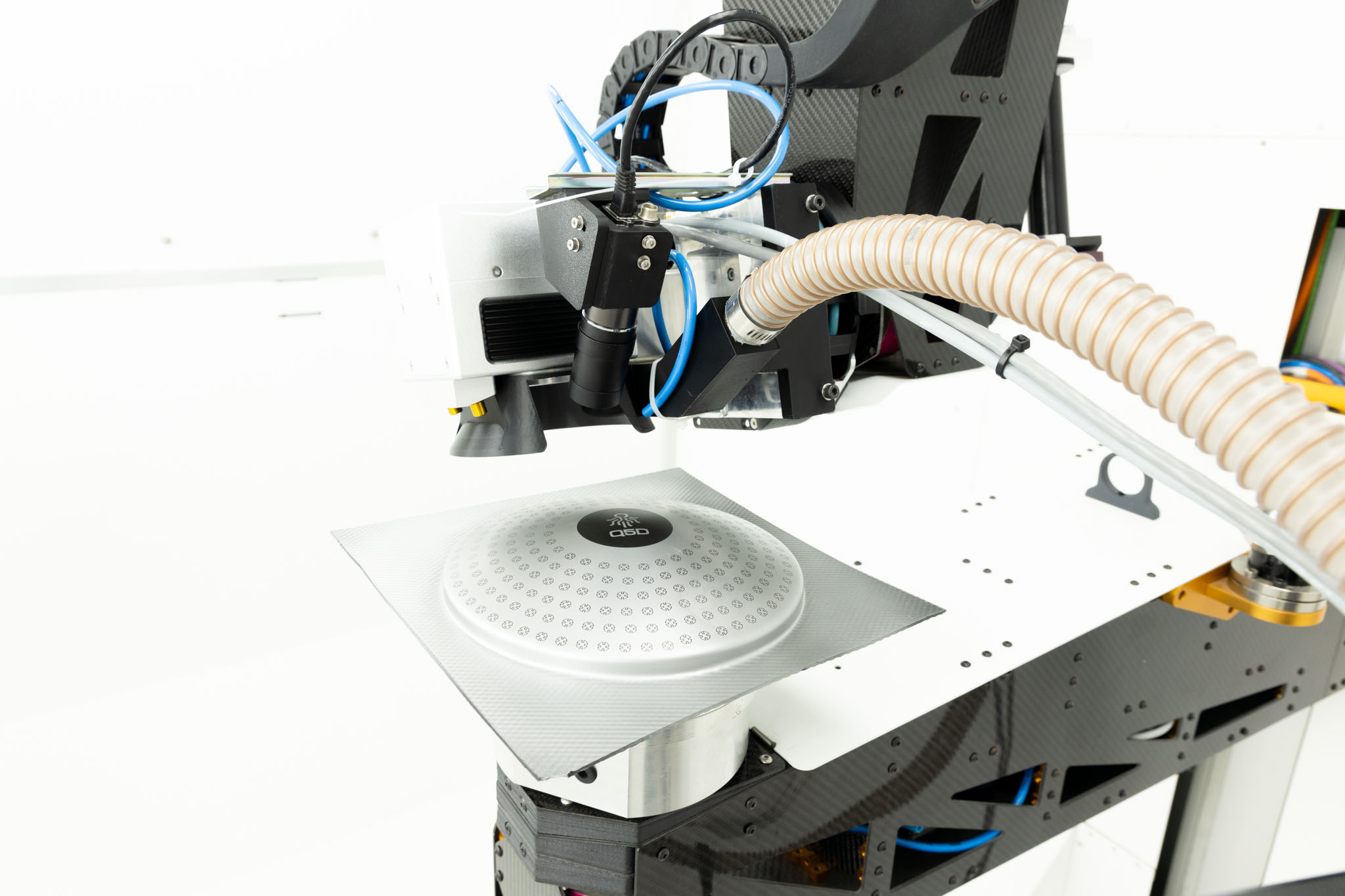

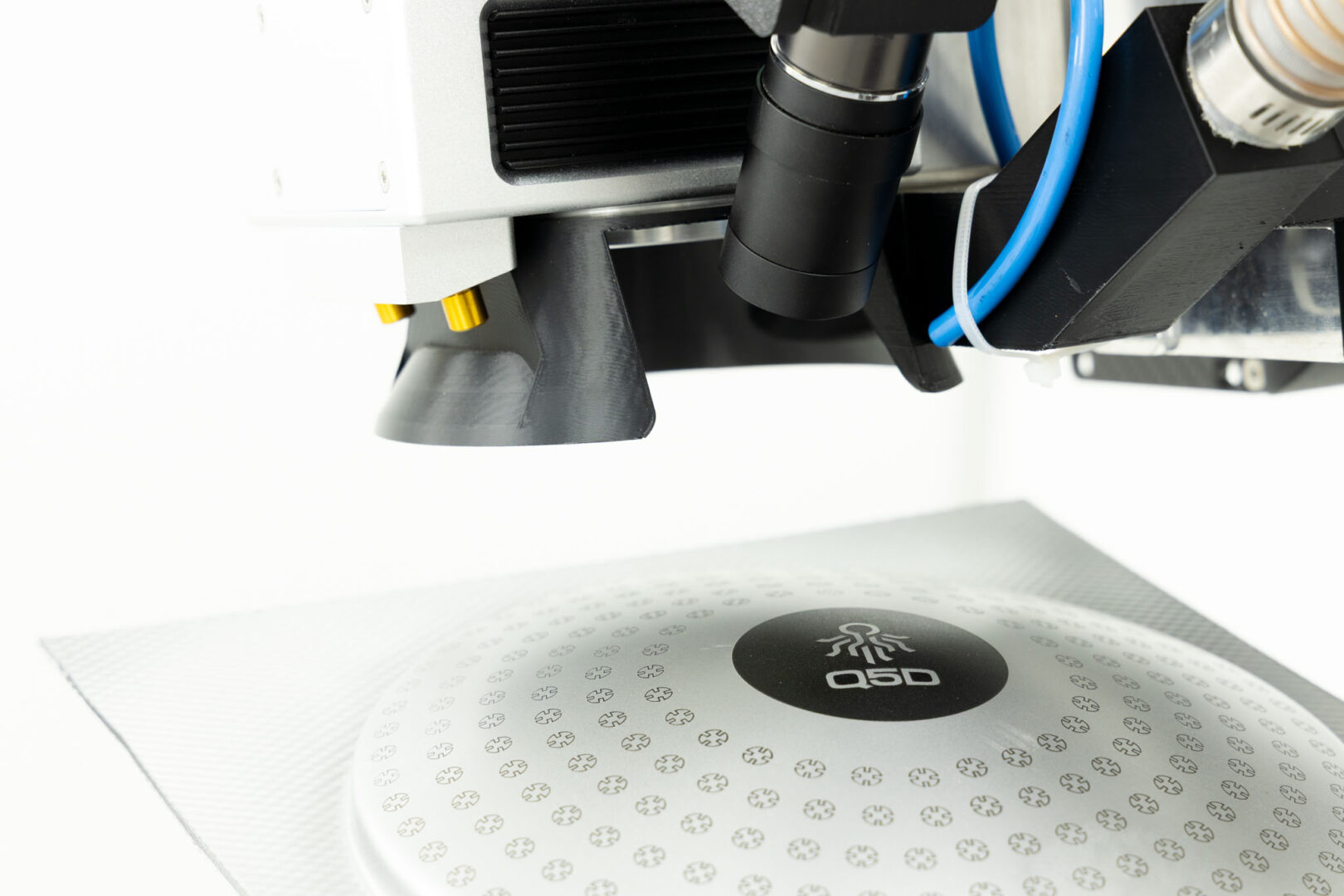

Based on the five-axis robotic cell that the company pioneered for automating wire harness manufacture, the new platform, called the CY10L, combines multi-axis motion control with a 100-Watt, 1064nm laser-assisted ablation and sintering head to create metal traces directly onto three-dimensional substrates. With a cylindrical one metre build envelope, the CY10L is particularly suited to working with large 3D components, allowing circuitry to follow complex contours rather than being limited to flat printed circuit boards.

The Q10L robotic cell enables high-precision, high-speed creation of conductive tracks onto large, complex three-dimensional (3D) substrates.

The CY10L’s print resolution is 150µm for copper or silver deposition and metal layers are typically between 1µm and 15µm thick, depending on the application. A full digital workflow from CAD to final product reduces prototype cycle times and allows rapid switching from product-to-product without re-tooling.

Ben Monteith, Q5D’s Laser and Applications Lead said, “The CY10L not only delivers the usual automation benefits of greater speed, precision, and productivity, but changes the way 3D components are made so dramatically that it creates a host of new design possibilities. Product designers can cut the cost, size and weight of their innovations while boosting consistency and reliability, even in the most critical applications.”

The CY10L is a 2.3-metre, steel-framed cube and can be used as a stand-alone machine or integrated directly into manufacturing lines. Customers can assess the technology at Q5D’s Technical Evaluation Centre (TAC) in Bristol, UK.

A white paper on the CY10L’s process technology is available here.

Q5D Contact

Simon Baggott

simon.baggott@q5d.com

Chief Marketing Officer

PR Agency Contact

Bob Jones, OriginalityB2B

bob.jones@originalityb2b.com