PRODUCTRONICA 2025: Q5D showcases vehicle headliner where wiring automation using a 5-axis robot has replaced conventional wire harnesses

PRODUCTRONICA 2025: Q5D showcases vehicle headliner where wiring automation using a 5-axis robot has replaced conventional wire harnesses

Ready to see Q5D in action?

Contact us to discuss your project.

The company is also announcing a strategic collaboration with J.A.M. for automating wiring termination.

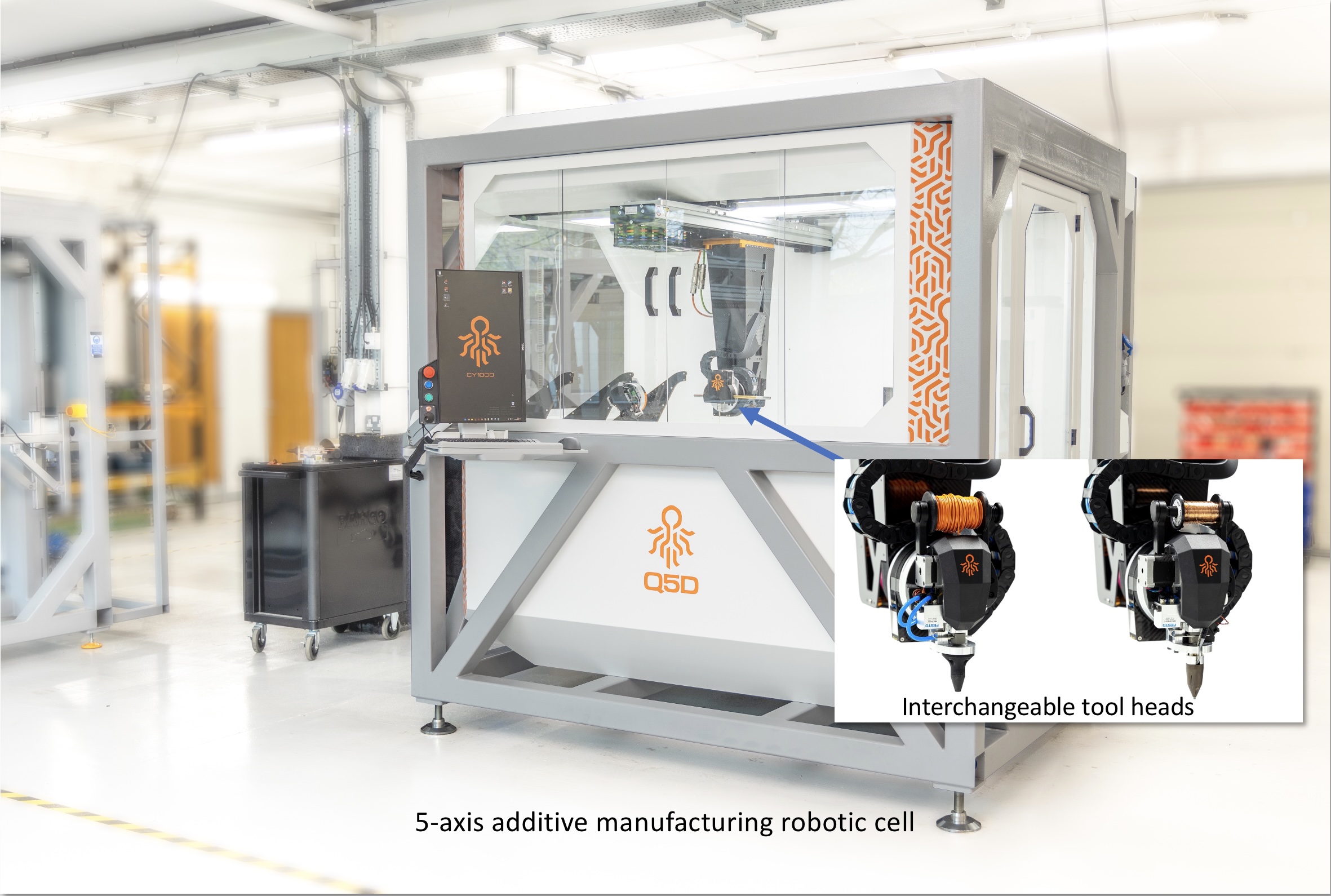

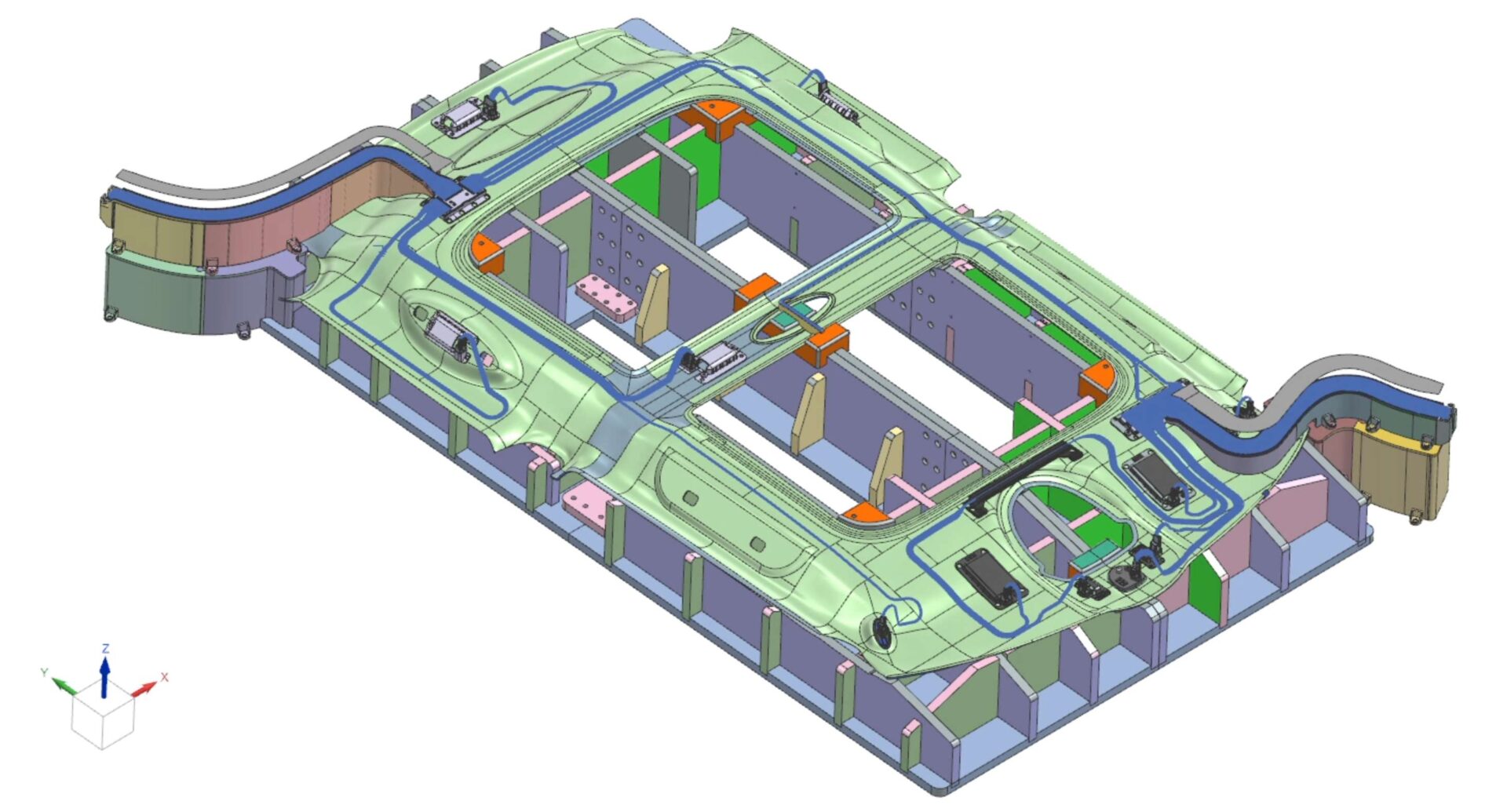

Bristol, UK, November 18, 2025: Q5D, a manufacturer of robotic cells that automate product electrification, is demonstrating at Productronica the technical and commercial benefits delivered by its world-leading technology. It is showcasing a real-world automotive headliner in which all wiring was implemented using one of the company’s 5-axis additive manufacturing robots. Q5D is also announcing a recent collaboration with J.A.M., a manufacturer of automated wiring termination machines that complement Q5D’s technology, at the event. Visit Q5D on Booth B5.159.

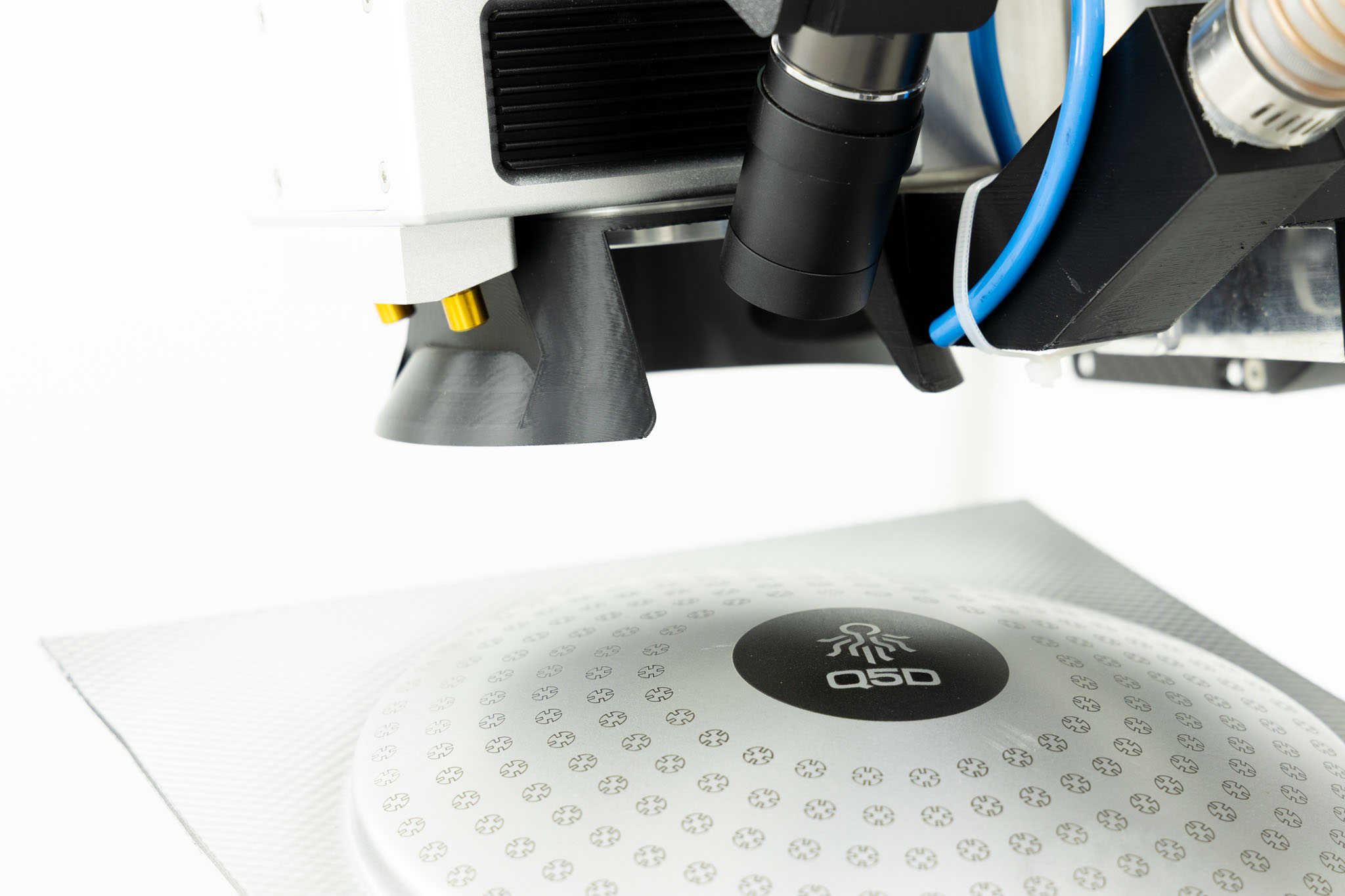

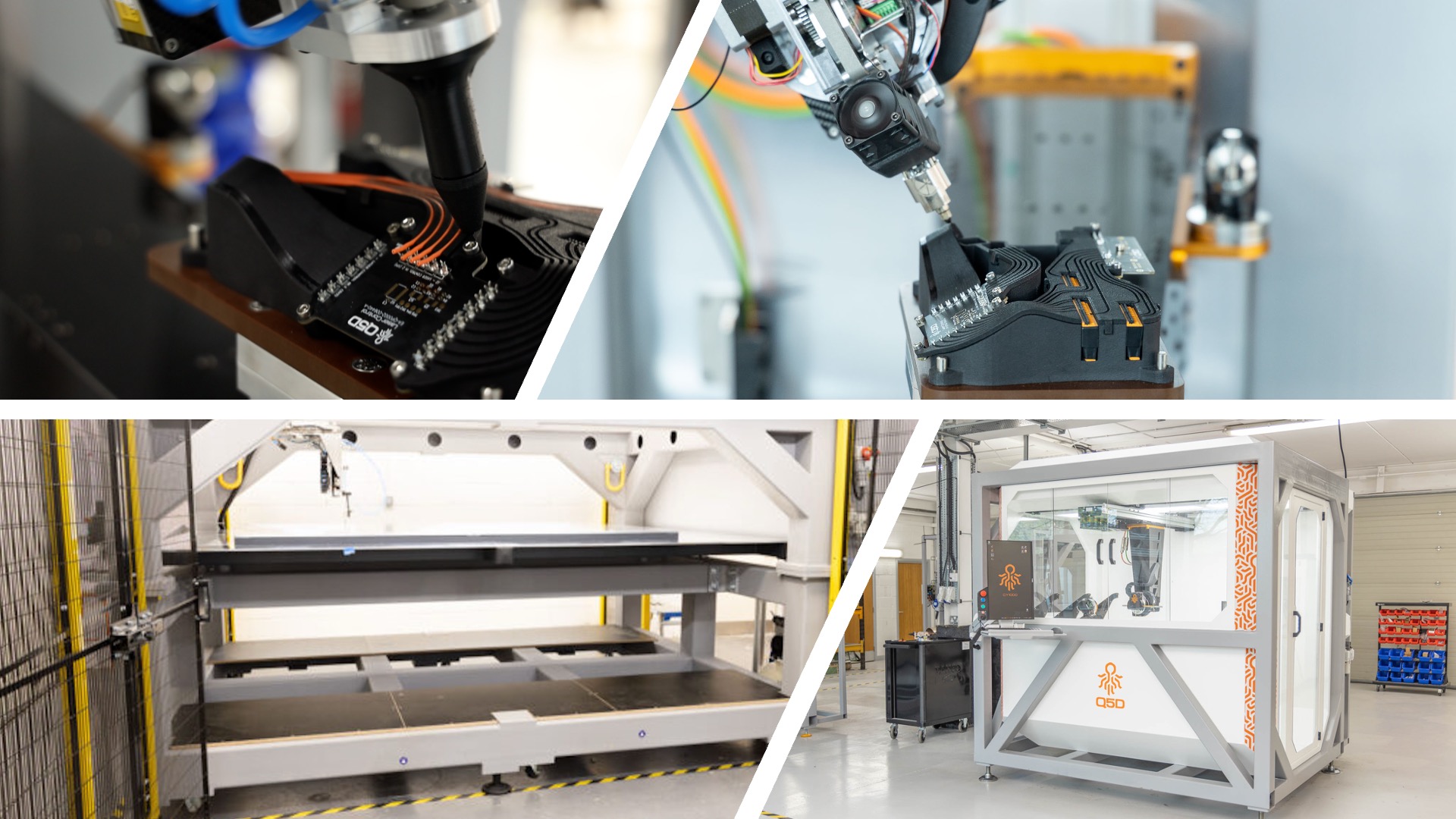

Q5D’s wiring automation robots streamline the production of intricate wiring harnesses. Employing a 5-axis additive manufacturing system, they precisely lay wiring onto products – such as vehicle headliners – by integrating bare or insulated wires, securing them, and making automatic terminations, all under the guidance of CAD-generated instructions. This method achieves notable space and weight reductions, minimises assembly errors, lowers manufacturing costs, and removes the need for manual processes traditionally required for wire harness construction. This facilitates shorter supply chains, making them more economical and secure by incorporating electrification directly at the final product assembly site.

CAD illustration of a vehicle headliner with embedded wiring

The collaboration agreement with J.A.M., which started when Q5D purchased semi-automatic wire crimping machines from the company, will facilitate joint product development to further integrate the products from the two companies and streamline manufacturing throughput.

Q5D’s CEO, Steve Bennington said: “Our initial experience with J.A.M. products and services has been outstanding. Accurate and consistent connector termination is critical to the reliability of electrical wiring in vehicles and other applications. J.A.M.’s long experience and technical innovation has ensured excellent compatibility with our unique processes, and both companies see many opportunities for mutually serving customers with systems that seamlessly integrate our complementary technologies.”

J.A.M.’s CEO, Masafumi Mizuno said: “Our collaboration with Q5D strategically aligns us with a disruptive force in next generation wiring technologies, unlocking growth and innovation opportunities. As a long-standing wire processing equipment manufacturer, we partner with forward-looking companies like Q5D to bring advanced solutions to our industry. This partnership strengthens our ability to offer a broader, integrated range of solutions, and we are confident JAM and Q5D will find multiple opportunities to collaborate and create value.”

About J.A.M.

Japan Automatic Machine Co., Ltd. (J.A.M.) is a global leader in industrial automation, renowned for precision processing and innovation since 1932. Headquartered in Tokyo with facilities across Asia, J.A.M. delivers advanced wire terminal crimping machines, presses, electronic connectors, and specialized tooling to the automotive and electronics sectors where reliability and high-volume precision are essential. Integrating IoT, predictive maintenance, and analytics into its equipment, J.A.M. maximises productivity and uptime while supporting flexible workforce needs. Its comprehensive ecosystem spans design, manufacturing, and after-sales support, cementing J.A.M.’s reputation as a trusted partner and technological leader in sustainable manufacturing. For more information, visit: https://www.jam-net.co.jp/eng/