PRODUCTRONICA PREVIEW: Q5D to demonstrate wiring automation robots that cut labour by 80% and support manufacturing onshoring at Productronica 2025

PRODUCTRONICA PREVIEW: Q5D to demonstrate wiring automation robots that cut labour by 80% and support manufacturing onshoring at Productronica 2025

Ready to see Q5D in action?

Contact us to discuss your project.

Bristol, UK, October 7, 2025, Productronica, Messe Munchen, November 18-25, Booth B4.159:

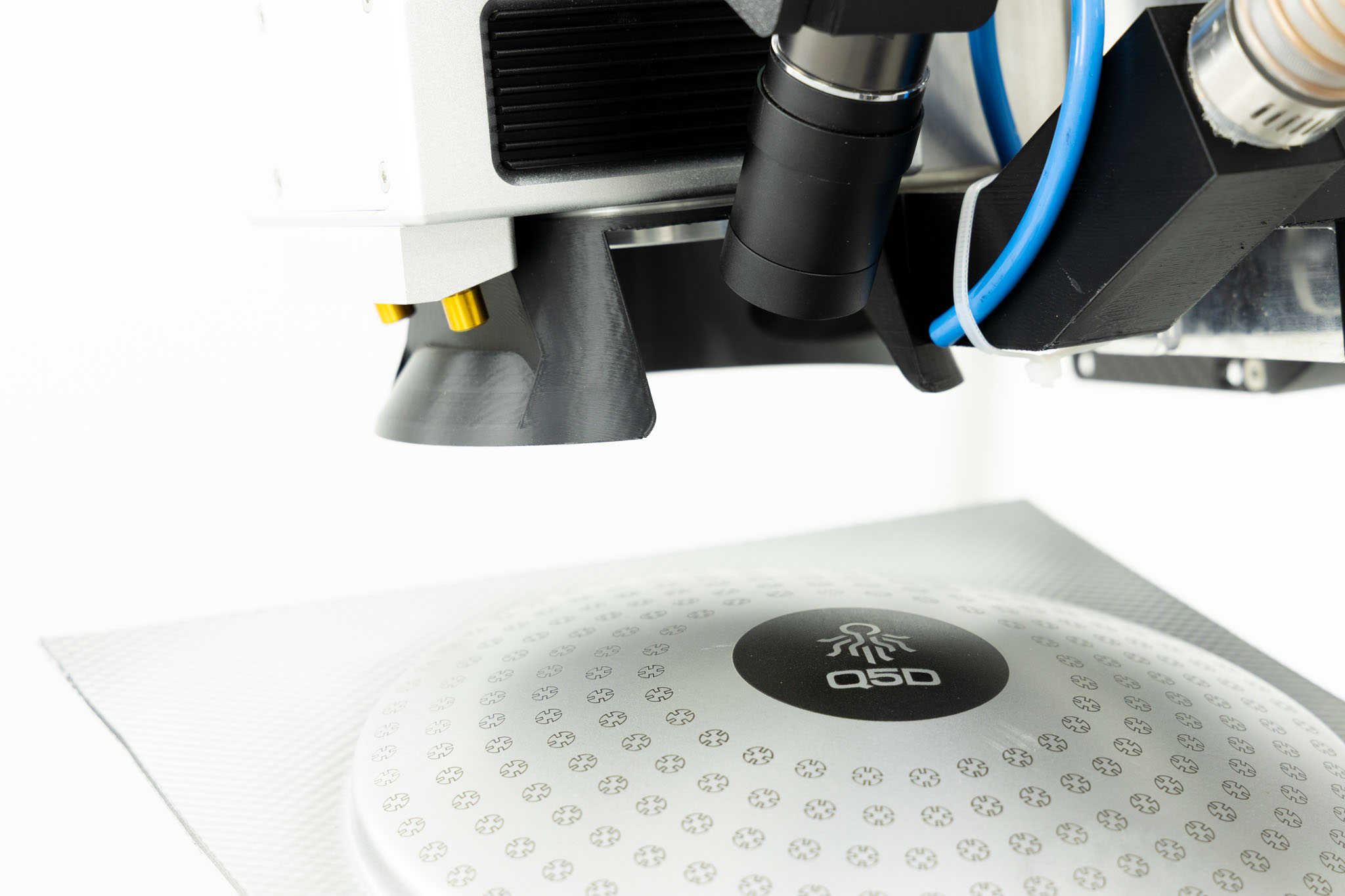

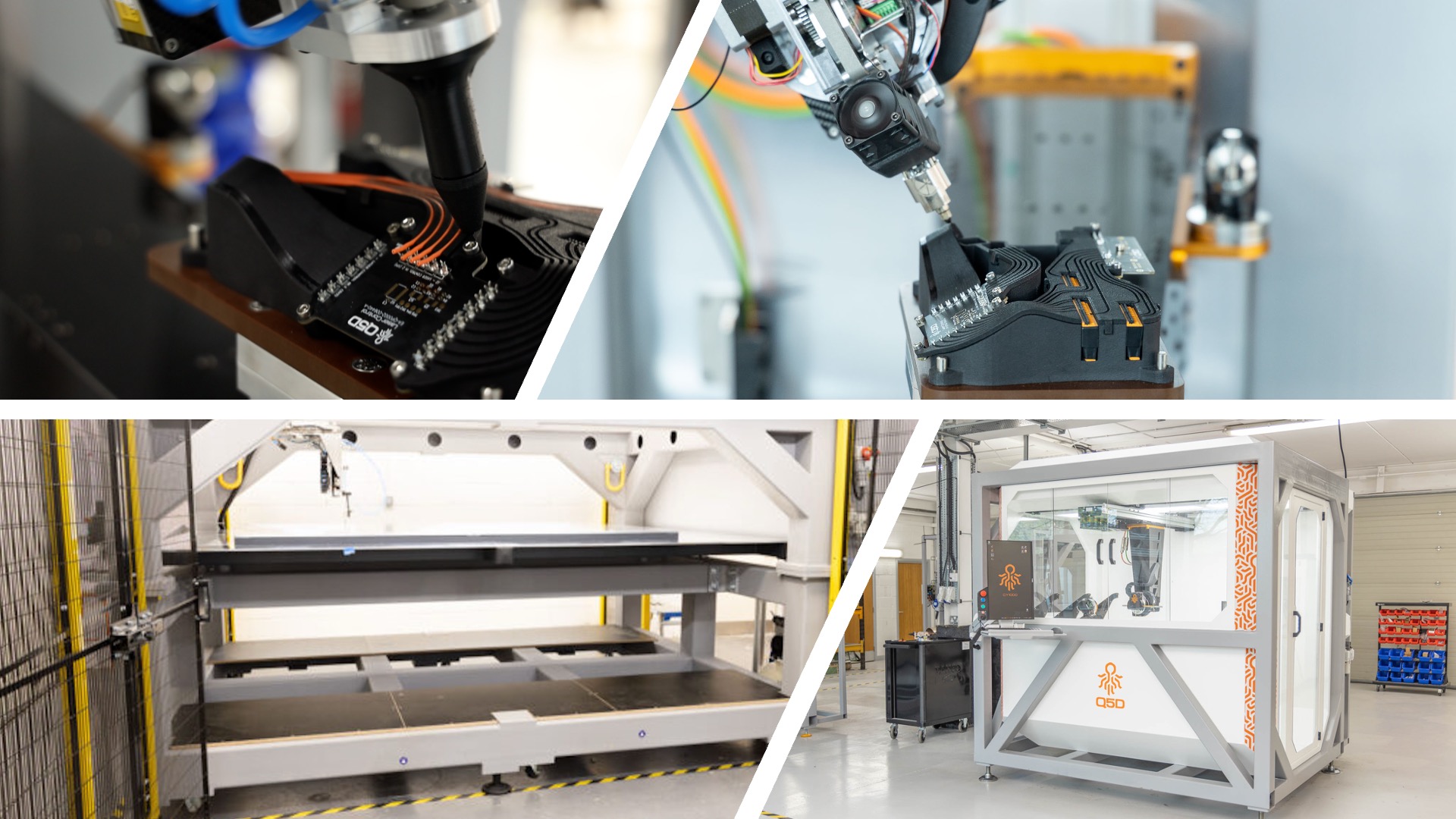

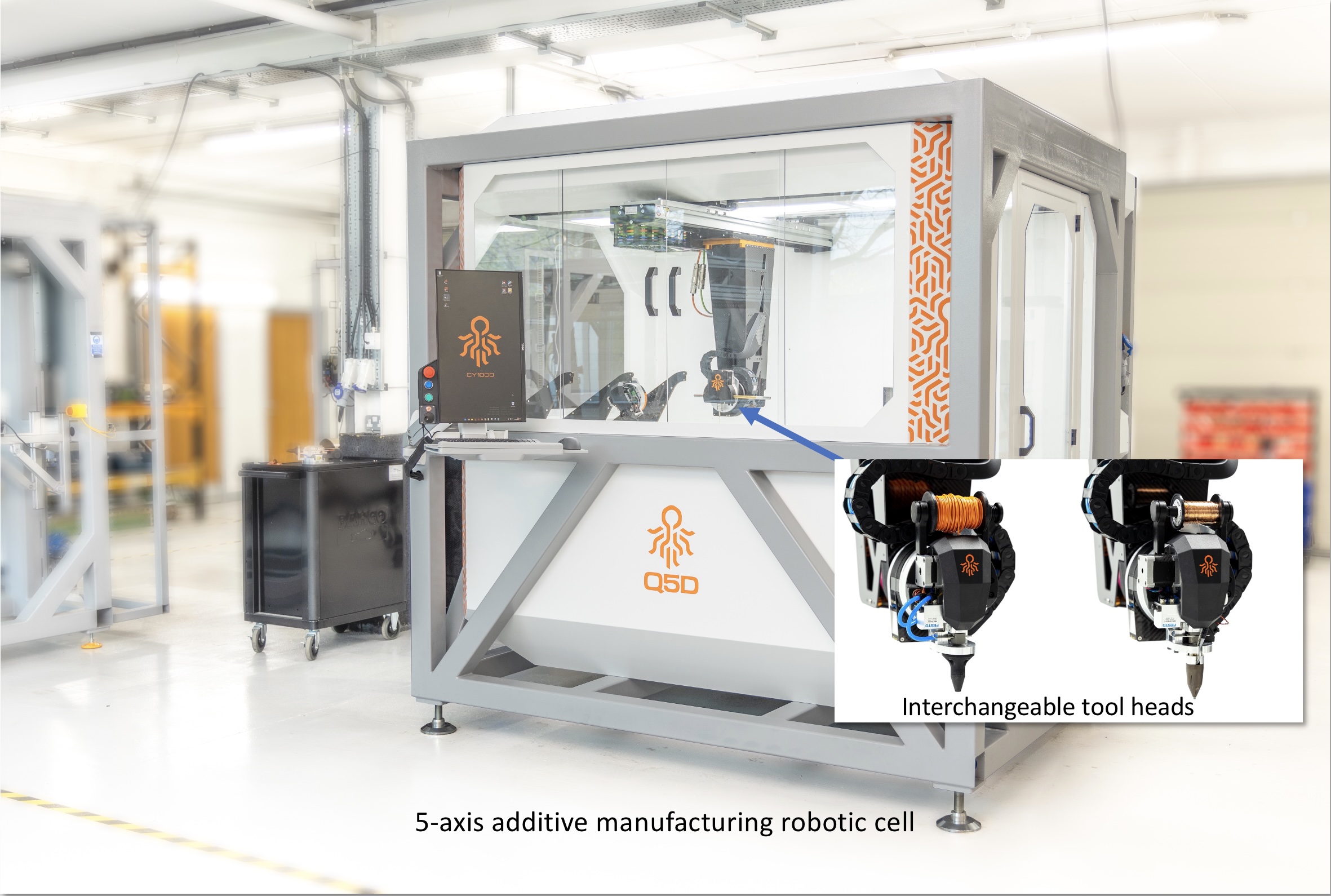

Q5D, a manufacturer of robotic cells for product electrification, will demonstrate how its wiring robots automate the manufacture of complex wire harnesses for automotive and industrial applications.

Using a 5-axis additive manufacturing process, the robots assemble wiring directly onto product components – like vehicle headliners – integrating bare or insulated wires, securing them in place, and terminating connections automatically, all guided by CAD-derived instructions for high precision. This approach saves substantial space and weight, reduces errors, lowers production costs, and cuts the manual labour associated with traditional wire harness assembly by 80% or more. It also enables electrification to be implement at the same location as final assembly, for example in car manufacturing plants, simplifying supply chains by onshoring.

Q5D’s technical experts will be on the booth to provide advice on specific applications.

Contact Peter Todd to arrange a meeting.