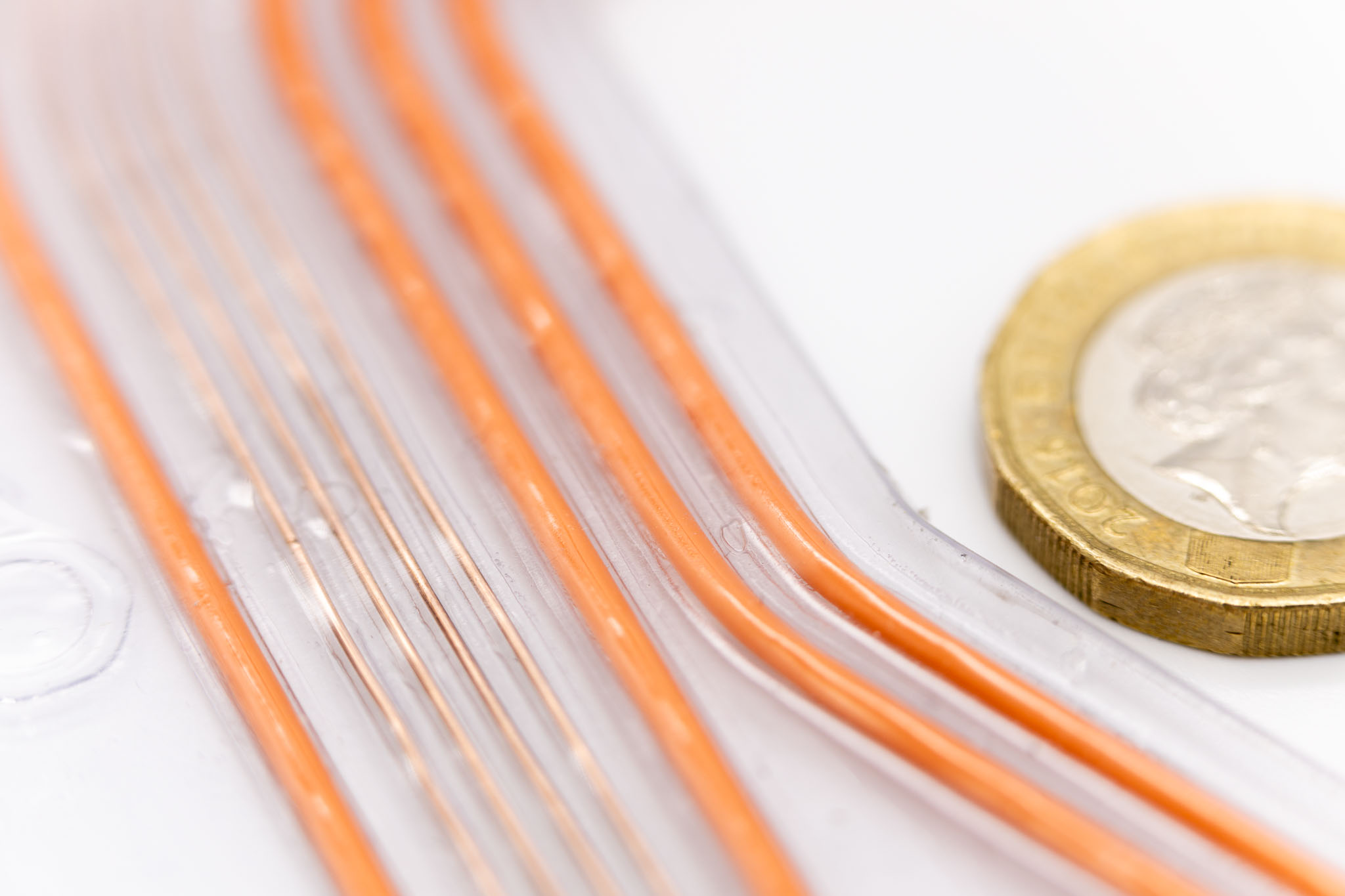

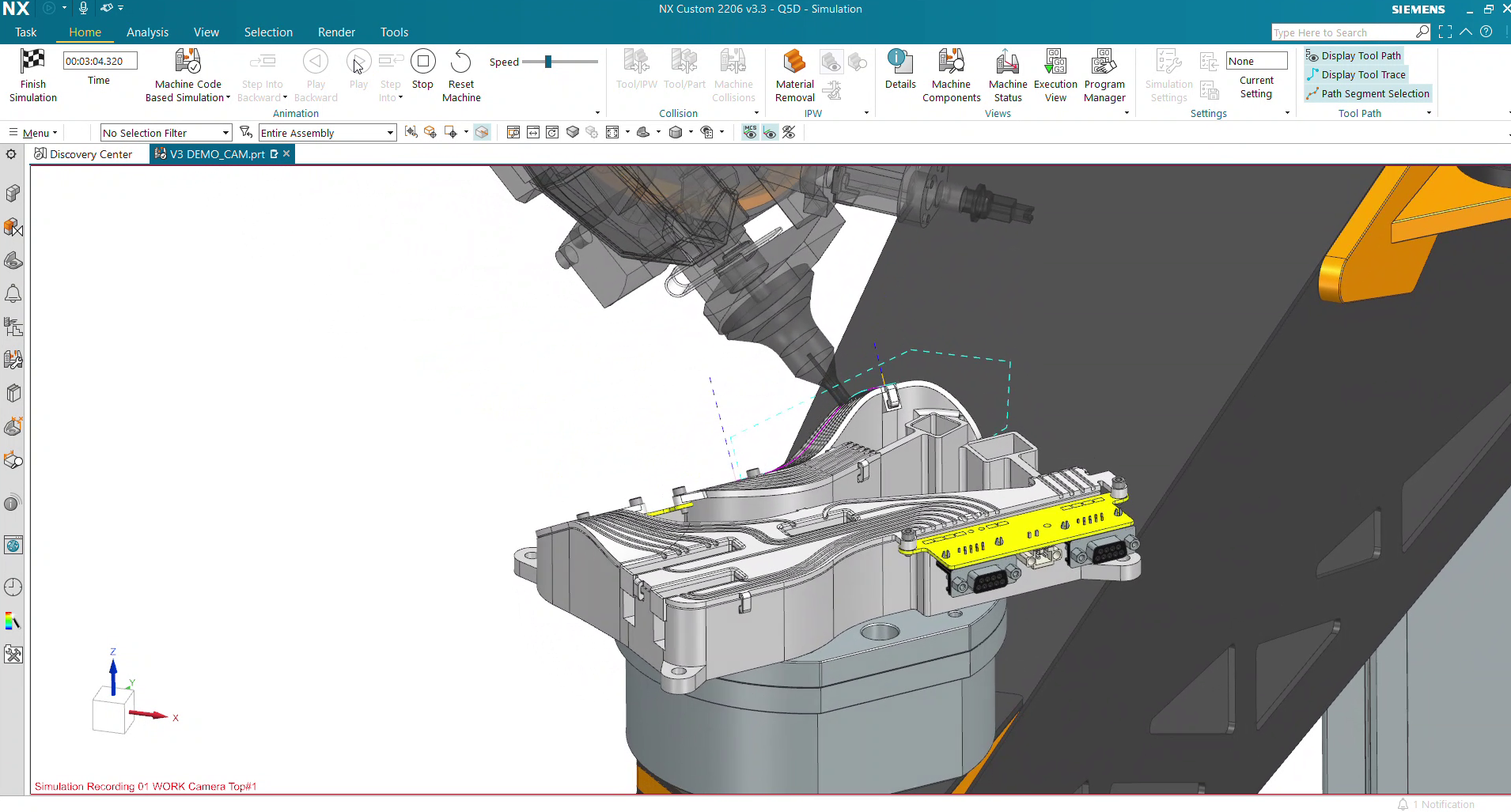

Robotic wire harness manufacturing

Reduce labour • Improve Quality • Simplify Supply Chains • Save cost •Reduce labour • Improve Quality • Simplify Supply Chains • Save cost •

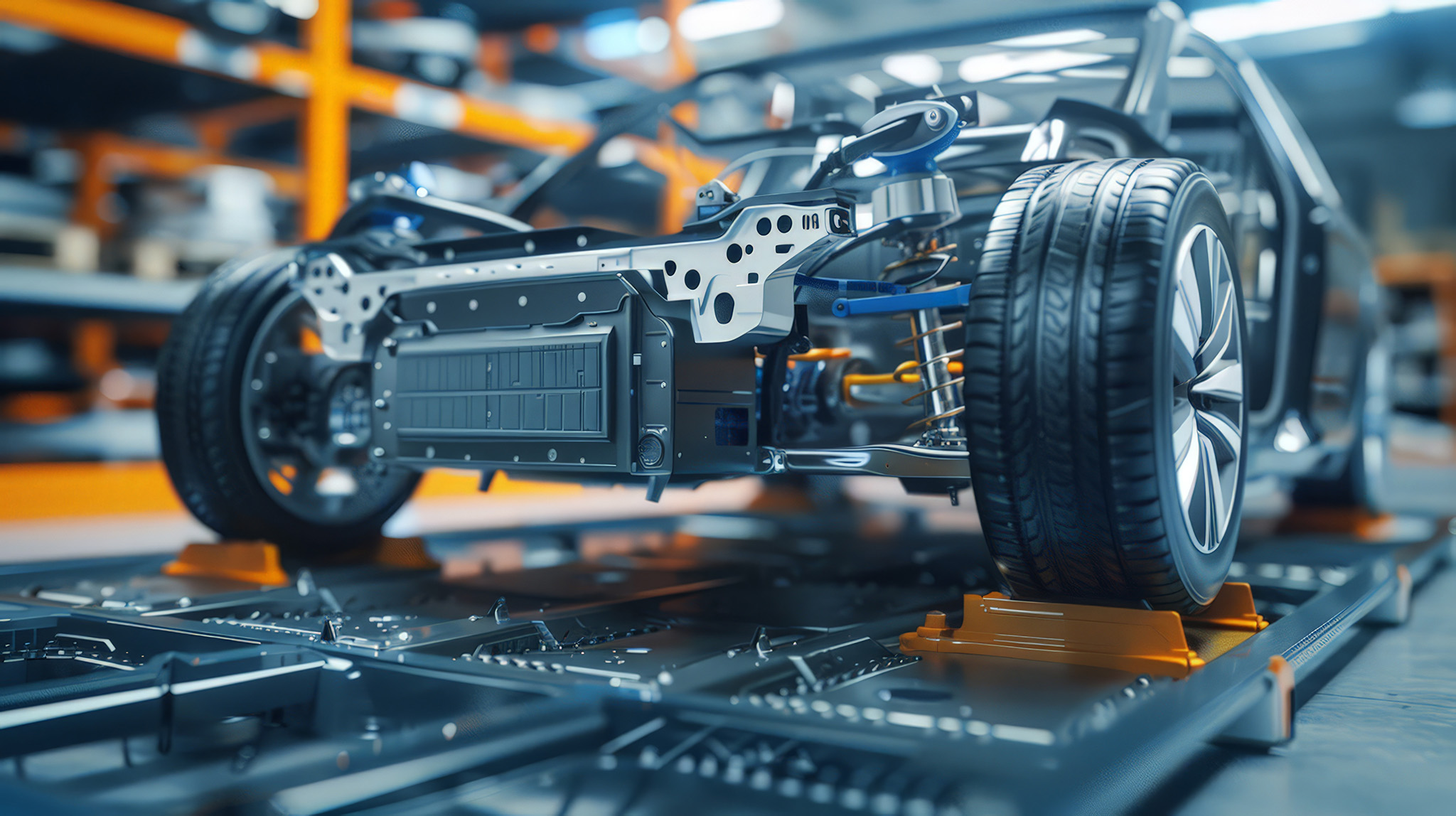

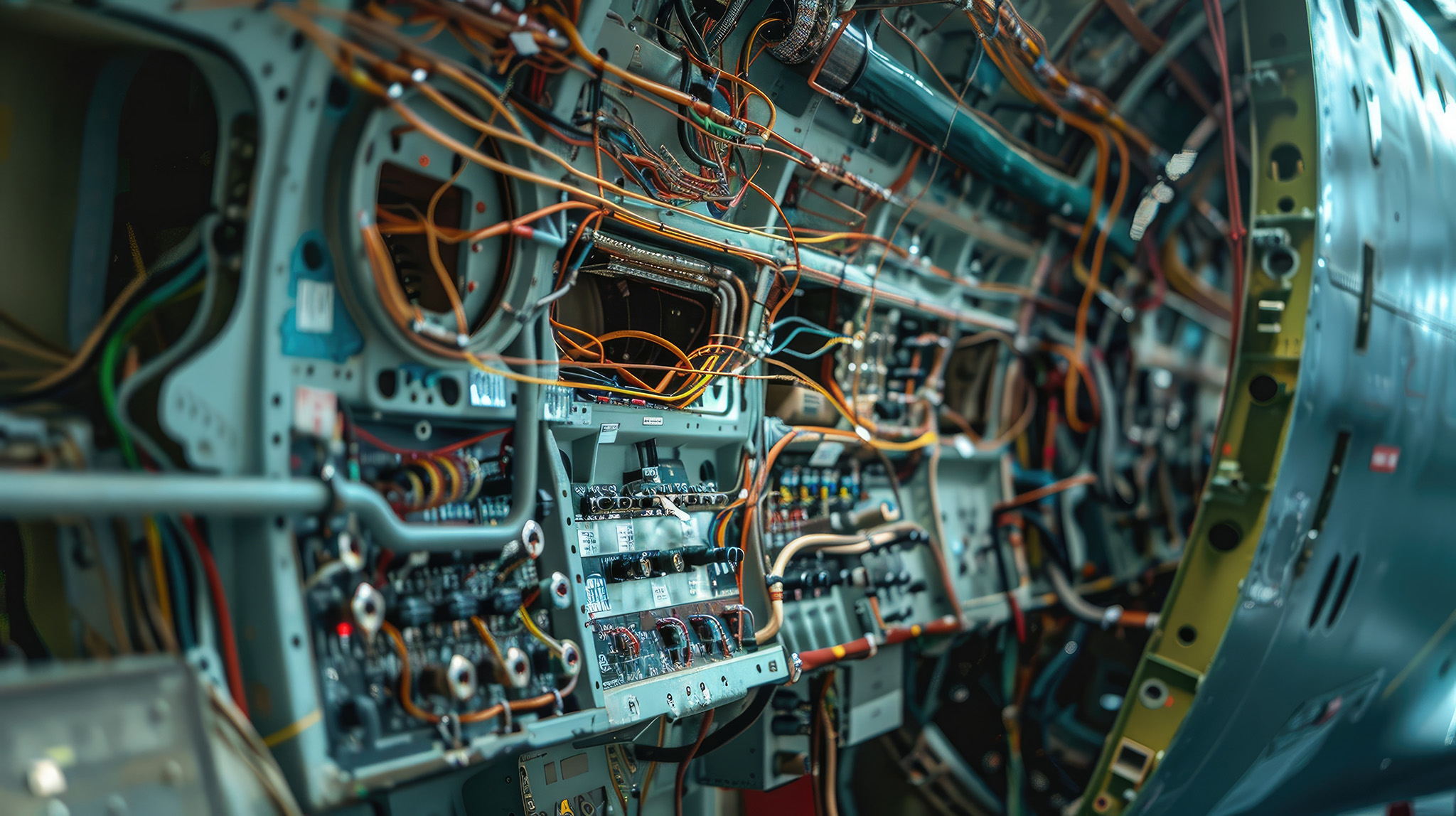

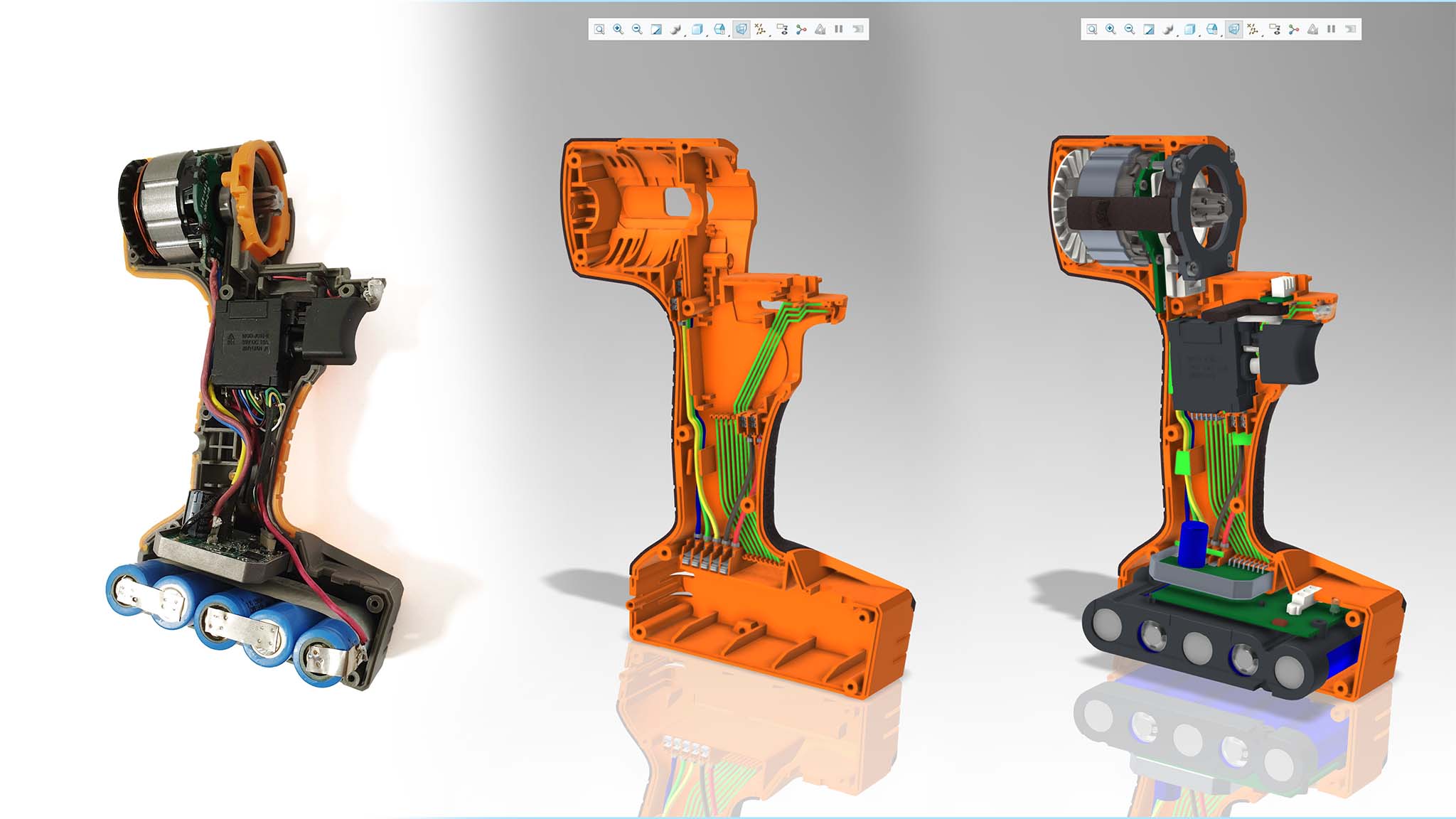

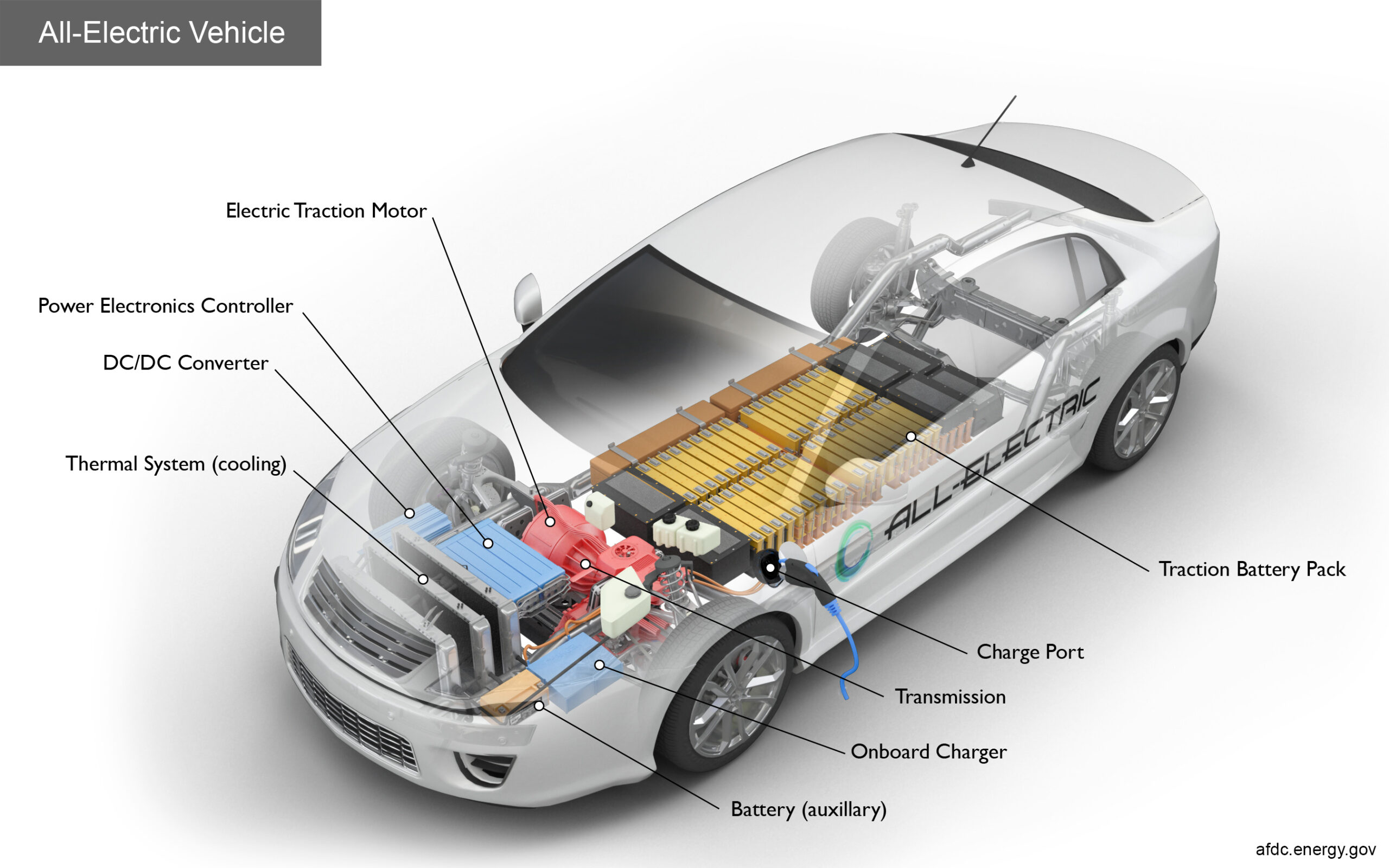

Where we’re making a difference

We are already showing an impact in many applications

Automation isn’t just about saving labour

There are many ways that our world-first technology can add value to your business.

For privacy reasons Vimeo needs your permission to be loaded. For more details, please see our Privacy Policy.