Introducing the Next Generation of 3D Additively Manufactured Electronics

Introducing the Next Generation of 3D Additively Manufactured Electronics

Ready to see Q5D in action?

Contact us to discuss your project.

Join us at Q5D with other industry leaders for our CY10-L Laser Product Launch and Live Demo on 21st January 2026!

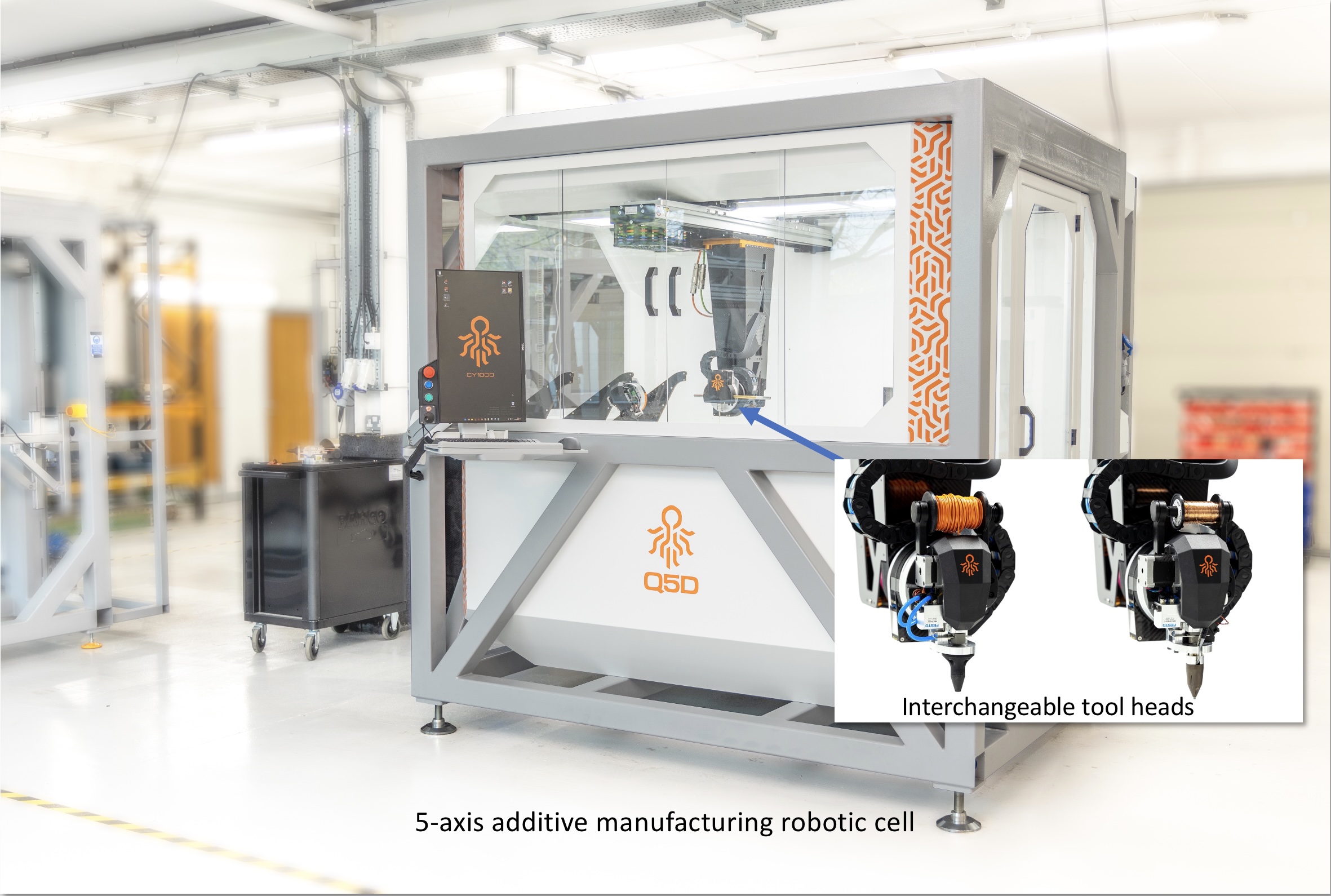

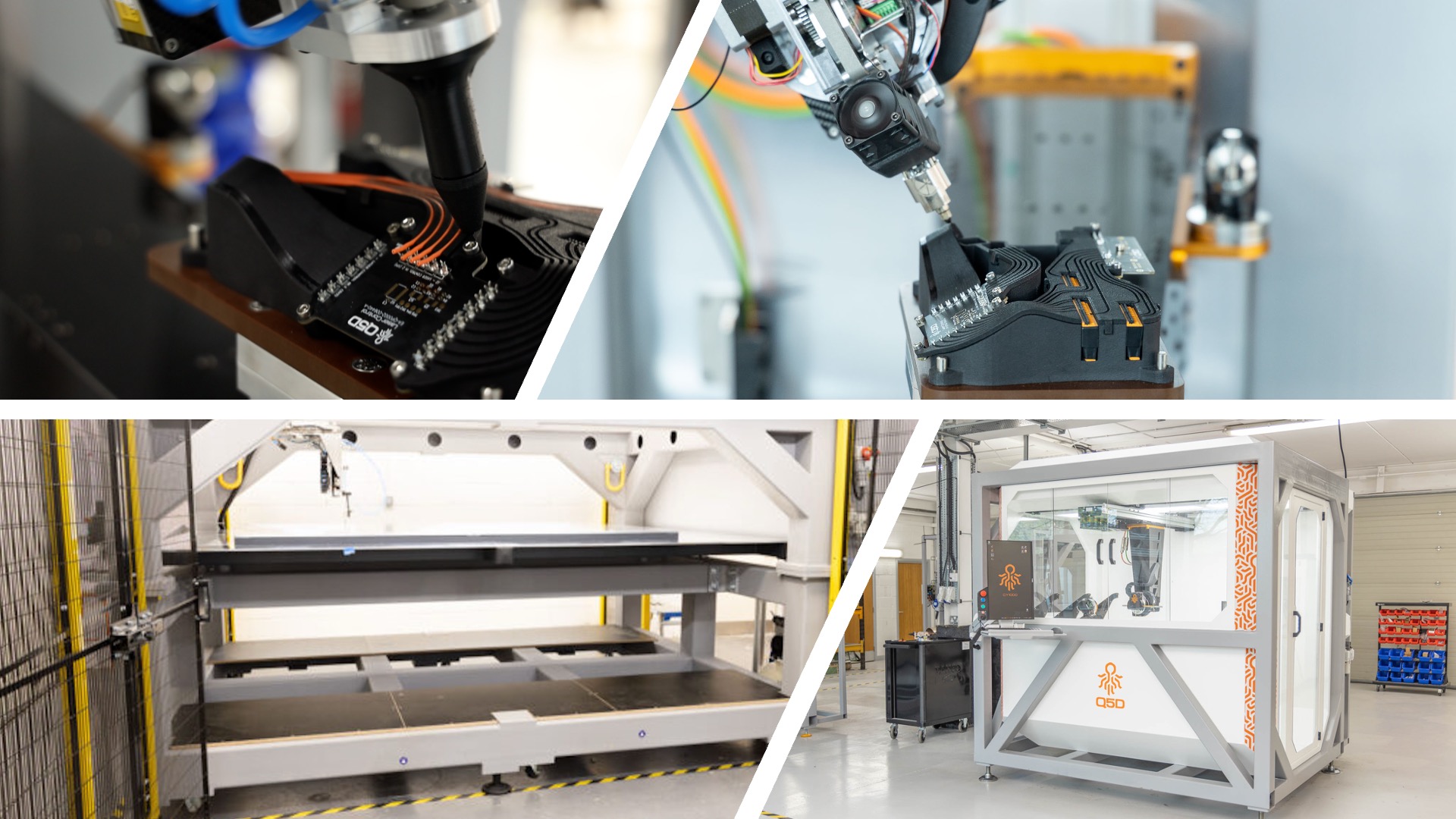

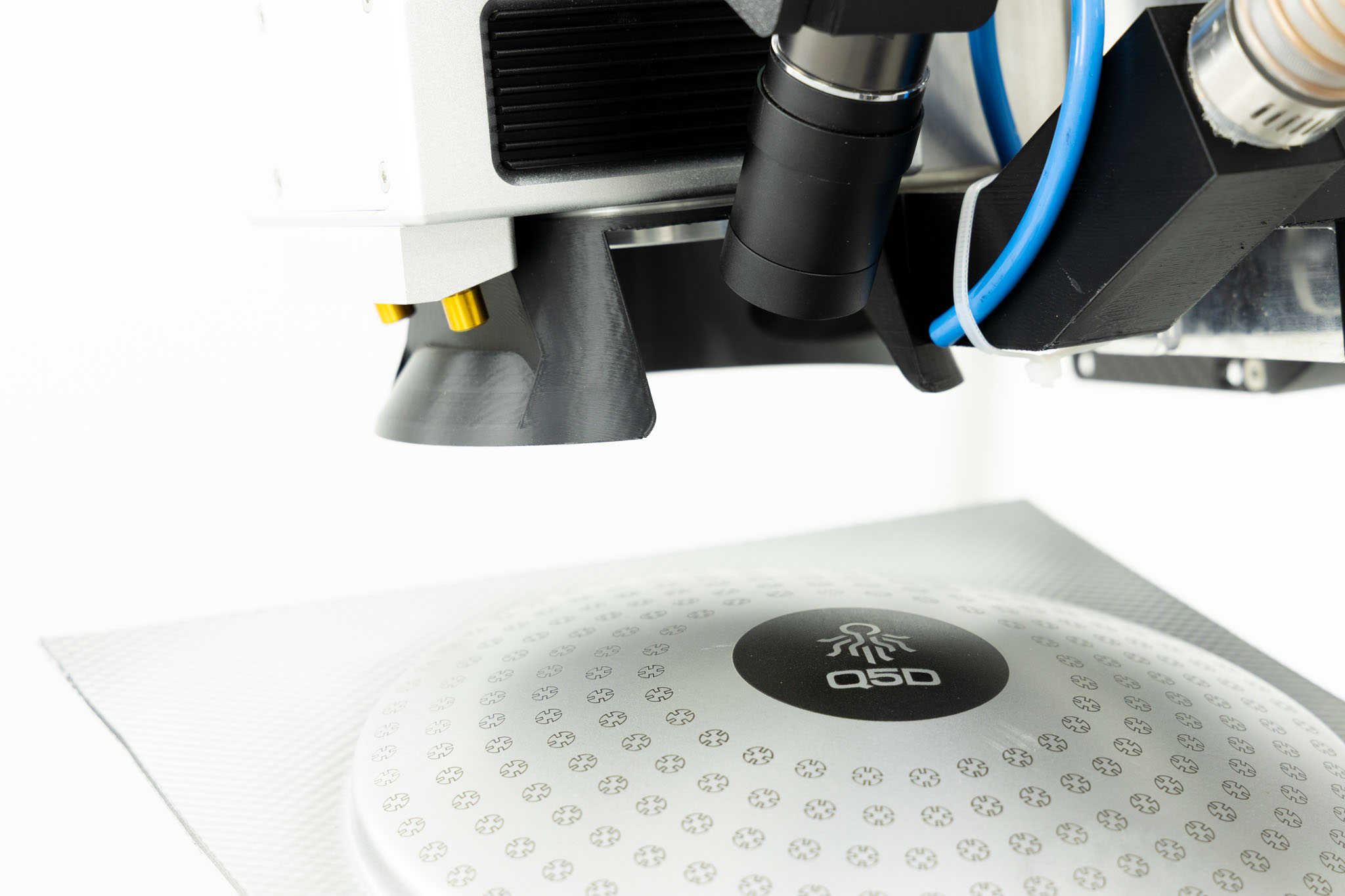

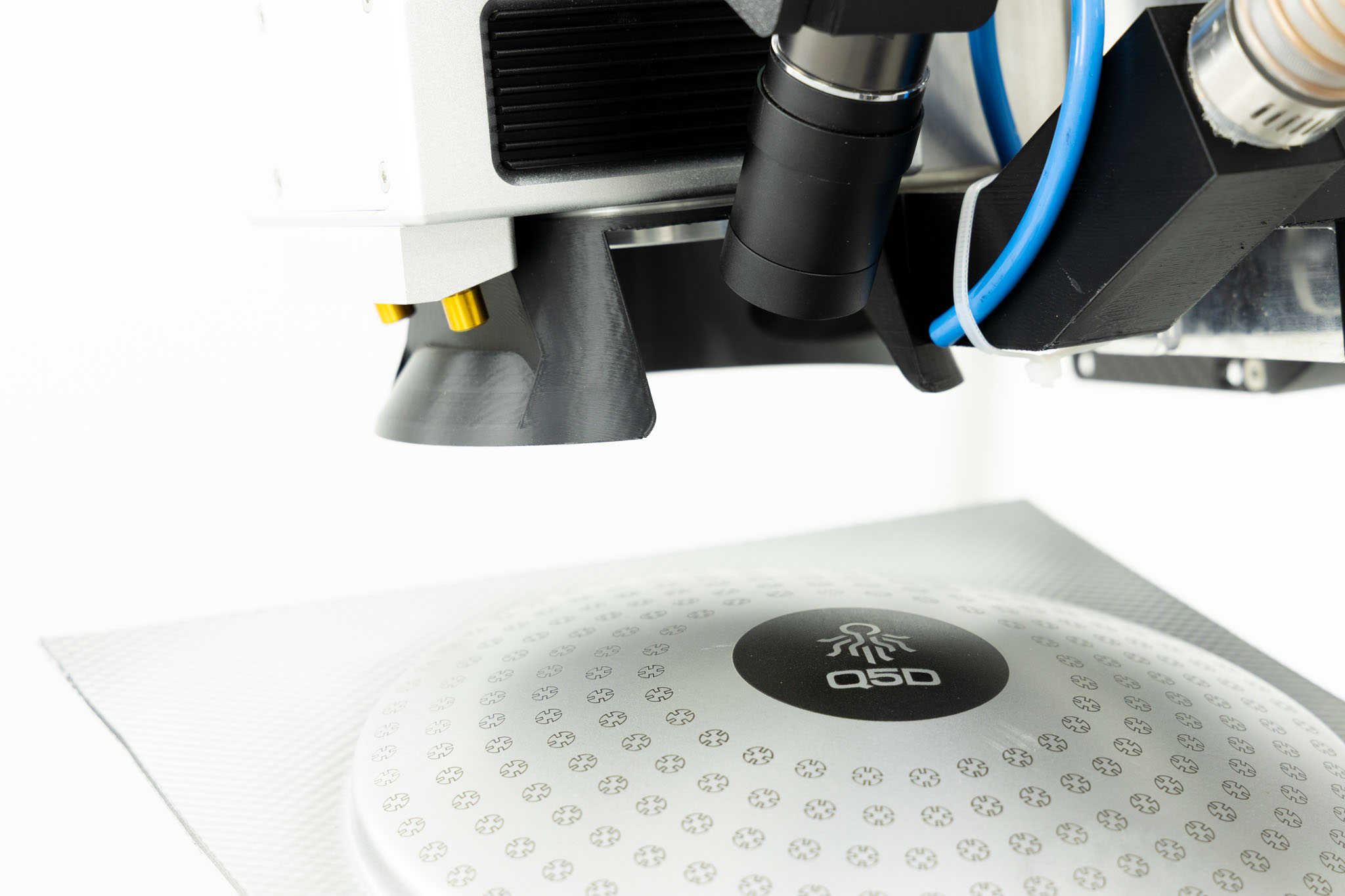

Q5D is transforming the way electronic functionality is integrated into complex 3D structures. Our new 5-axis laser metallisation system delivers precision, speed, and flexibility to enable antennas, sensors, and conductive tracks on large, curved surfaces without the limitations of traditional methods.

Conventional techniques lack full 3D capability, have limited working volumes, and require specialized substrates. Q5D’s platform solves these challenges:

Enables New Designs

5-axis capability, and a large working volume, increases design freedom, allowing previously challenging shapes to be metallised on large 3D parts.

Full digital manufacturing

Our digital workflow reduces prototype cycle time, and allows rapid switching from product to product without re-tooling

Excellent performance

Rapid, high resolution (~150um) metallisation with excellent conductivity, on diverse substrates, creating high quality, inexpensive parts, produced at scale

Progress and Market Opportunity

Our technology can be used to make curved antennas, metamaterials and automotive touch controls. We have demonstrated laser based selective metallisation of on a variety of substrates (aerospace dielectrics, ceramics, range of plastics)

Unlike competing technology such as Laser Direct Structuring, which relies on a specialist nano particle loaded substrate, our process can work with a wide variety of substrates, making it possible to choose materials better suited to the application.

Strategic Investment Opportunity

Q5D recently secured $10.6M in equity and UK government innovation loans in our Series A round. We are now opening the round to strategic investors who see long-term alignment.

Apart from the reduction in cost and improvement in quality that automation brings there are many potential reasons for exploring investment in Q5D, including:

A fully digital manufacturing process for agile product development

• Agile product evolution

• Flexible low-volume custom manufacturing

Reduce reliance on manual labour

• Hedge against manual processes and labour costs

• Increased quality and complexity of product

To register for the launch and demo event (in person or online) please follow the links below

In person:

Location: Q5D Technologies Ltd, Harbour Place, Serbert Road, Portishead, North Somerset, BS20 7GF, UK Navigate to Q5D

Date & Time: Wed 21/01/2026 1100 GMT

Register Here: https://q5d.com/cy10l-event-registration/