Why Electrical Function Integration?

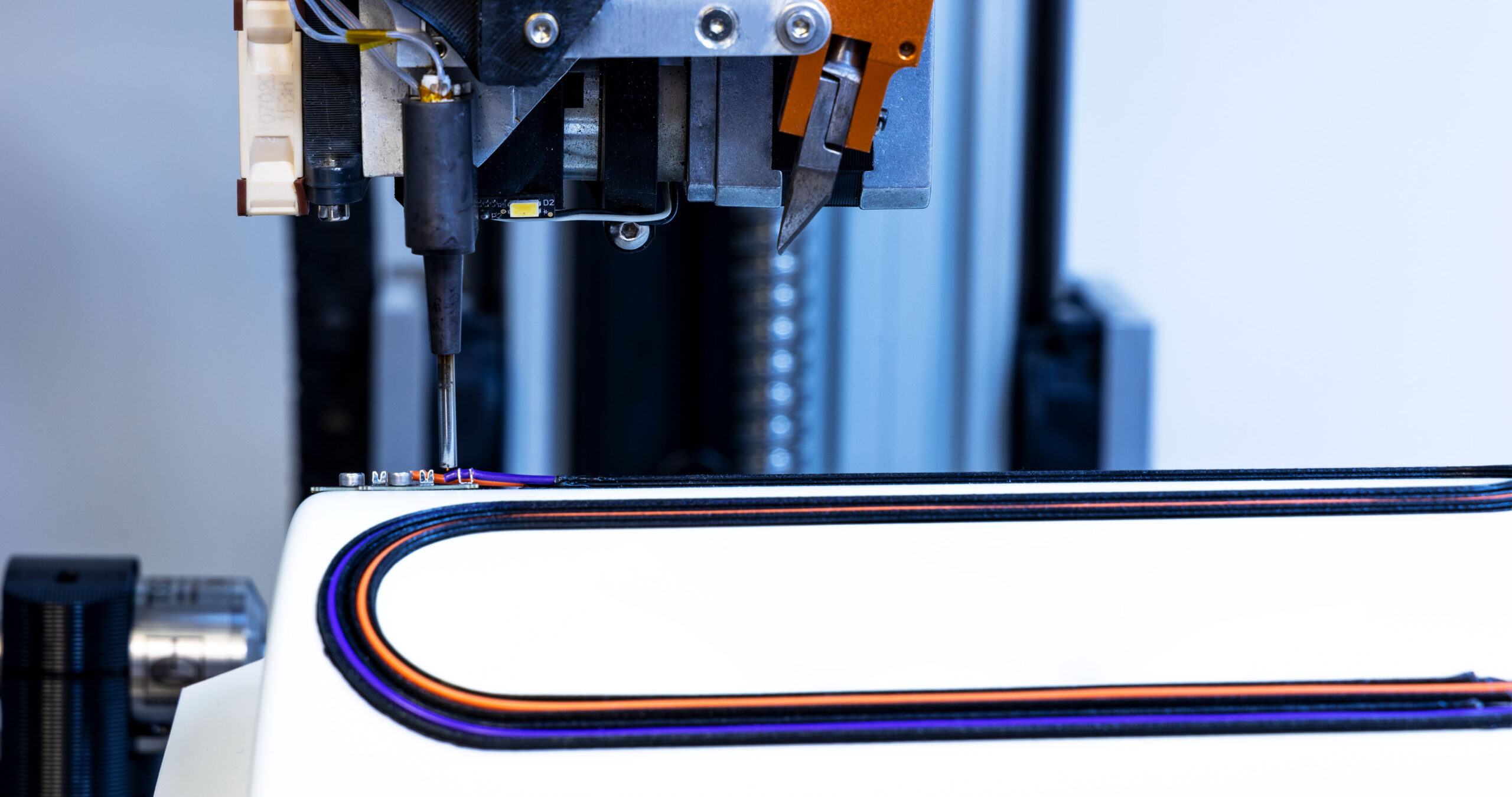

Electrical Function Integration (EFI) is how we describe our manufacturing processes. We don’t just offer an alternative way of making wiring harnesses, but the ability to change the design of products for the better, by adding electrical components and wiring to complex metallic, ceramic and polymeric surfaces.

Securing wiring directly to the surface of the product means that wiring no longer needs to be flexible. Traditionally wiring has to be flexible and sized to accommodate assembly.

Overlaying conductors, connectors and wiring with polymer gives protection from mechanical and environmental damage and leads to more durable products.

EFI places the control over exactly where components, wire, conductors and connectors are in the hands of the designer. Product packaging is improved, releasing space for additional functions and, because the wiring no longer needs to withstand mechanical stresses, weight can be saved.

EFI case studies

Manufacturing seats and cabin interiors for commercial aircraft is highly labour intensive. The range of customisation required from airline [...]