Whitepaper CY10L – Laser-based selective metallisation for 3D electronics 2026

Whitepaper CY10L – Laser-based selective metallisation for 3D electronics 2026

Ready to see Q5D in action?

Contact us to discuss your project.

WHITEPAPER:

Q5D Laser-Based Metallisation for 3D Electronics

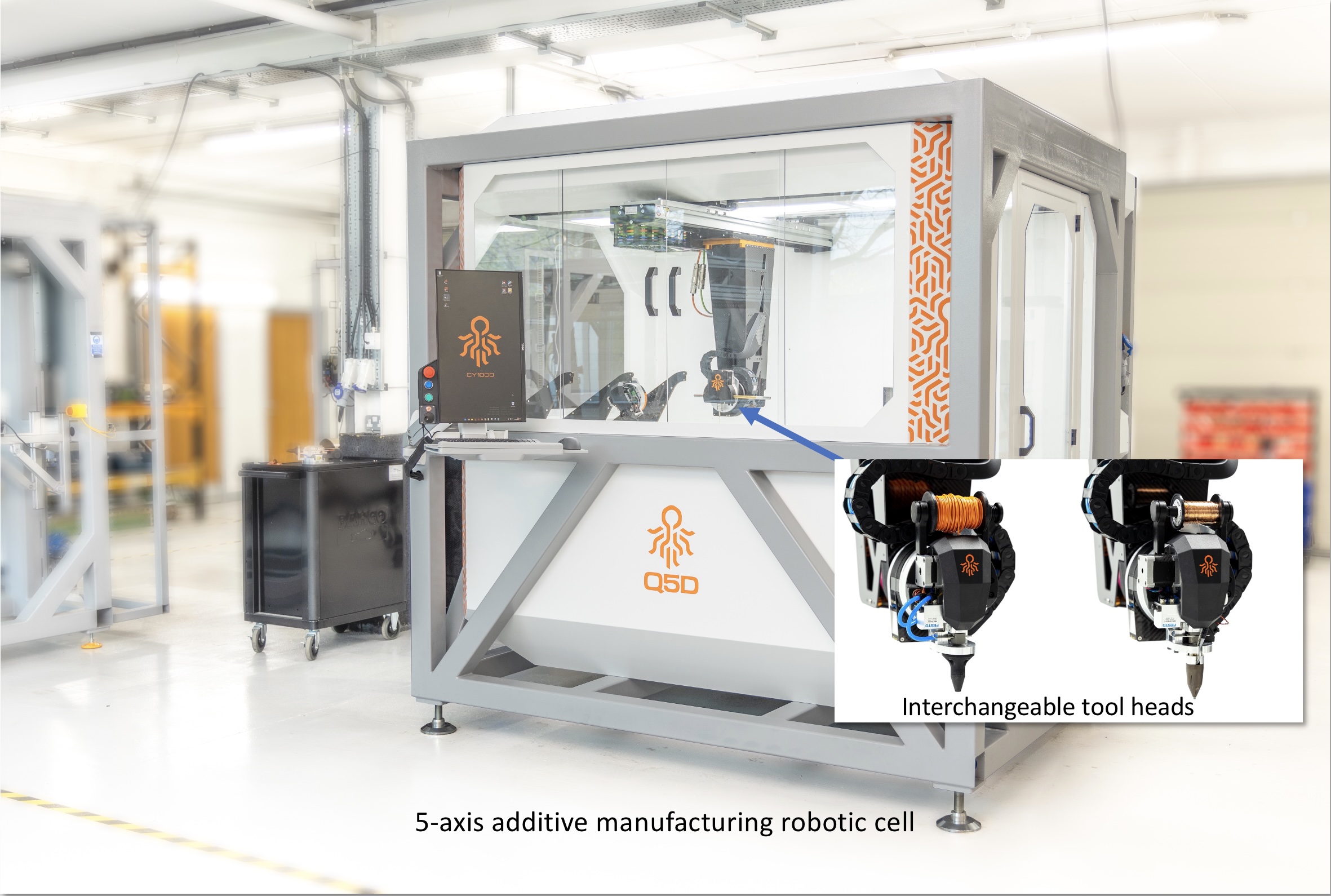

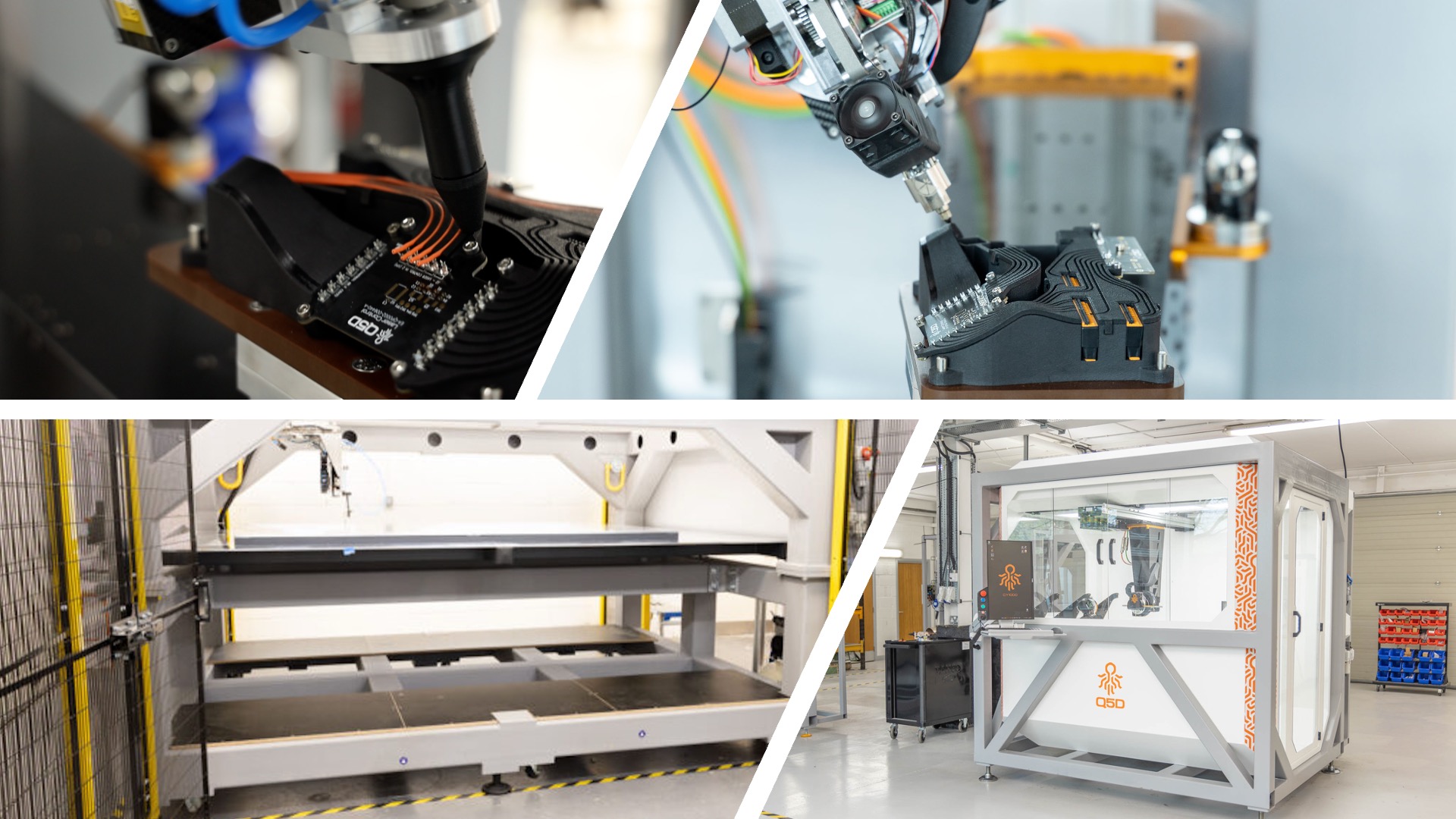

- Company Overview: Q5D is a UK-based robotics and software company specializing in Additively Manufactured Electronics (AME) using advanced CAD/CAM and 5-axis robotic platforms.

- AME Benefits:

- Integrates electronics into 3D structures for weight reduction and design flexibility.

- Reduces material waste and accelerates production cycles.

- Market projected to reach $60B by 2030.

- Q5D Technology:

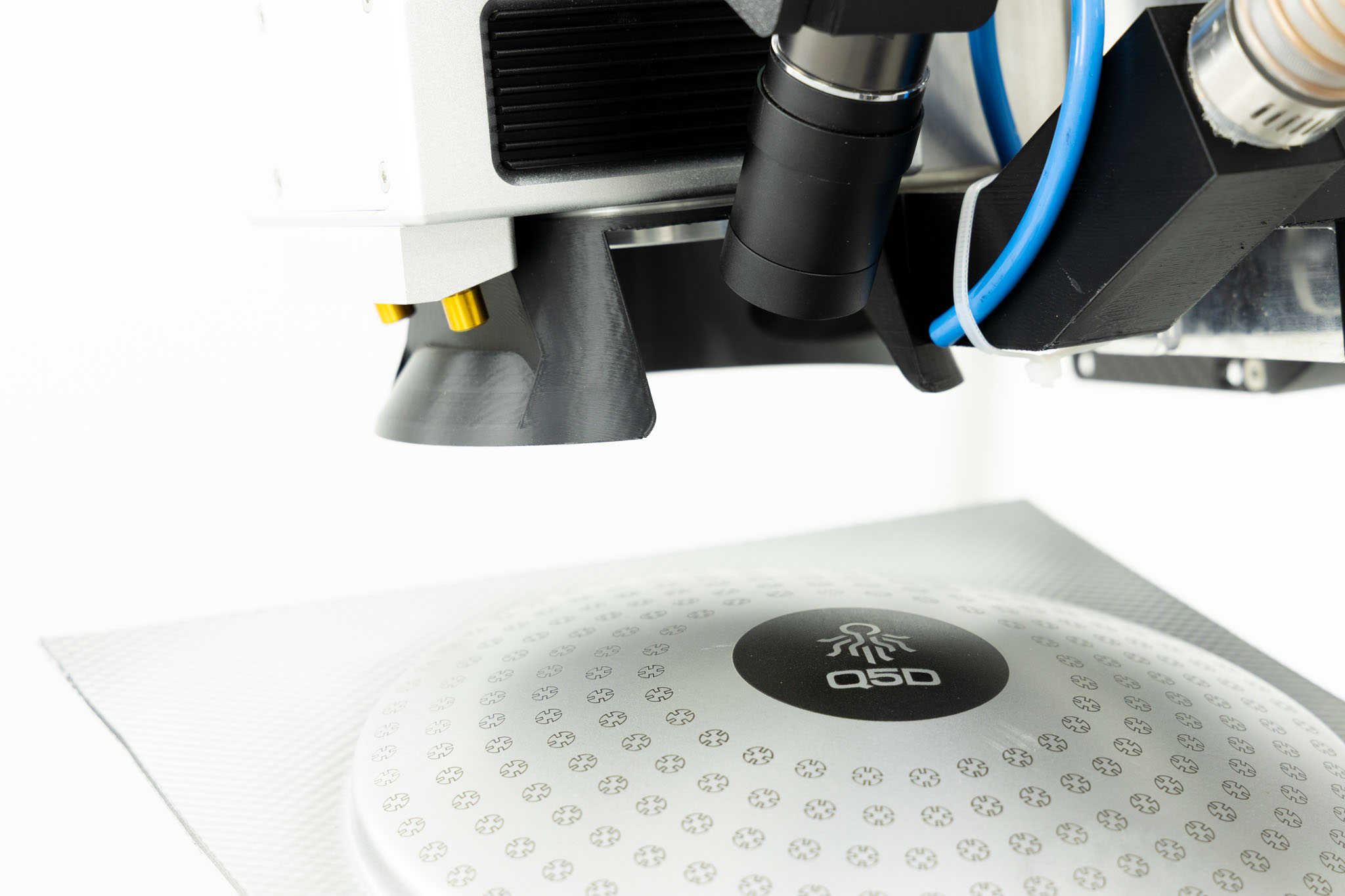

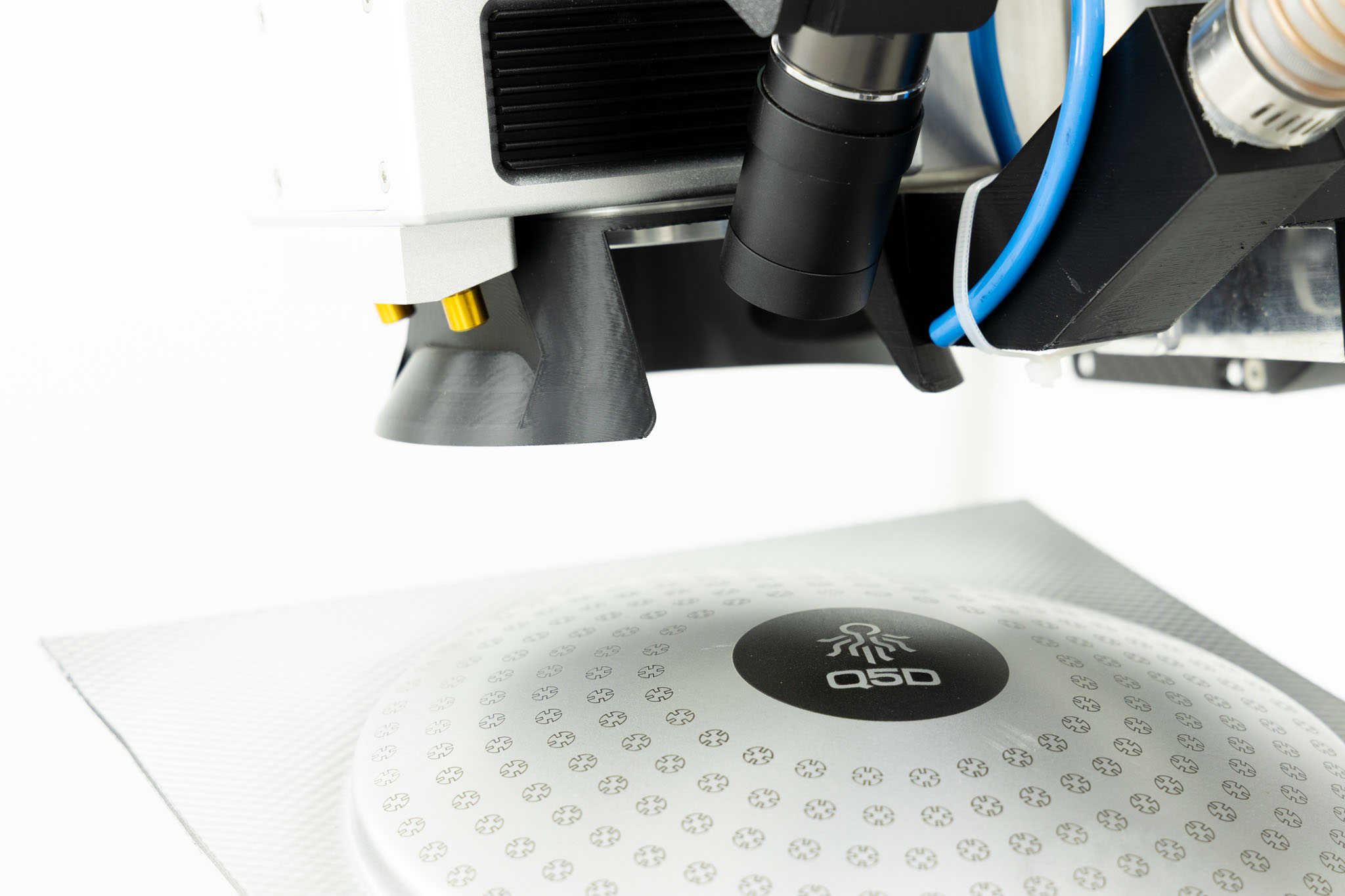

- CY10-L machine: 5-axis platform with 100W fibre laser and ultrasonic spray deposition.

- Handles large parts (up to 1 × 0.5 × 0.5 m).

- Achieves fine resolution (≤100 μm) and high speed (>2 m/s).

- Fully digital workflow for automation and scalability.

- Process Steps:

- Coat surface with conductive material (silver/copper).

- Laser ablation for fine-feature tracks.

- Laser sintering for conductivity

- Alternatively mask ablation followed by copper electroless plating for near bulk conductivity

- Advantages Over Competing Methods:

- Substrate agnostic and highly versatile.

- Eliminates reliance on intermediary films or specialist substrates.

- Faster and more precise than inkjet or LDS.

- Applications:

- Antennas, capacitive elements, frequency-selective surfaces on complex 3D geometries.

- Aerospace, automotive, and consumer electronics.

- Key Benefits:

- Large component compatibility.

- Tuneable conductivity.

- Improved design flexibility and reduced time-to-market.

Whitepaper:

To access the whitepaper – Please click here