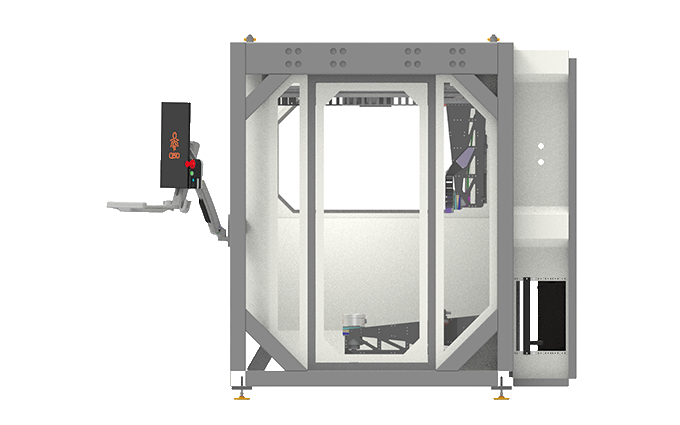

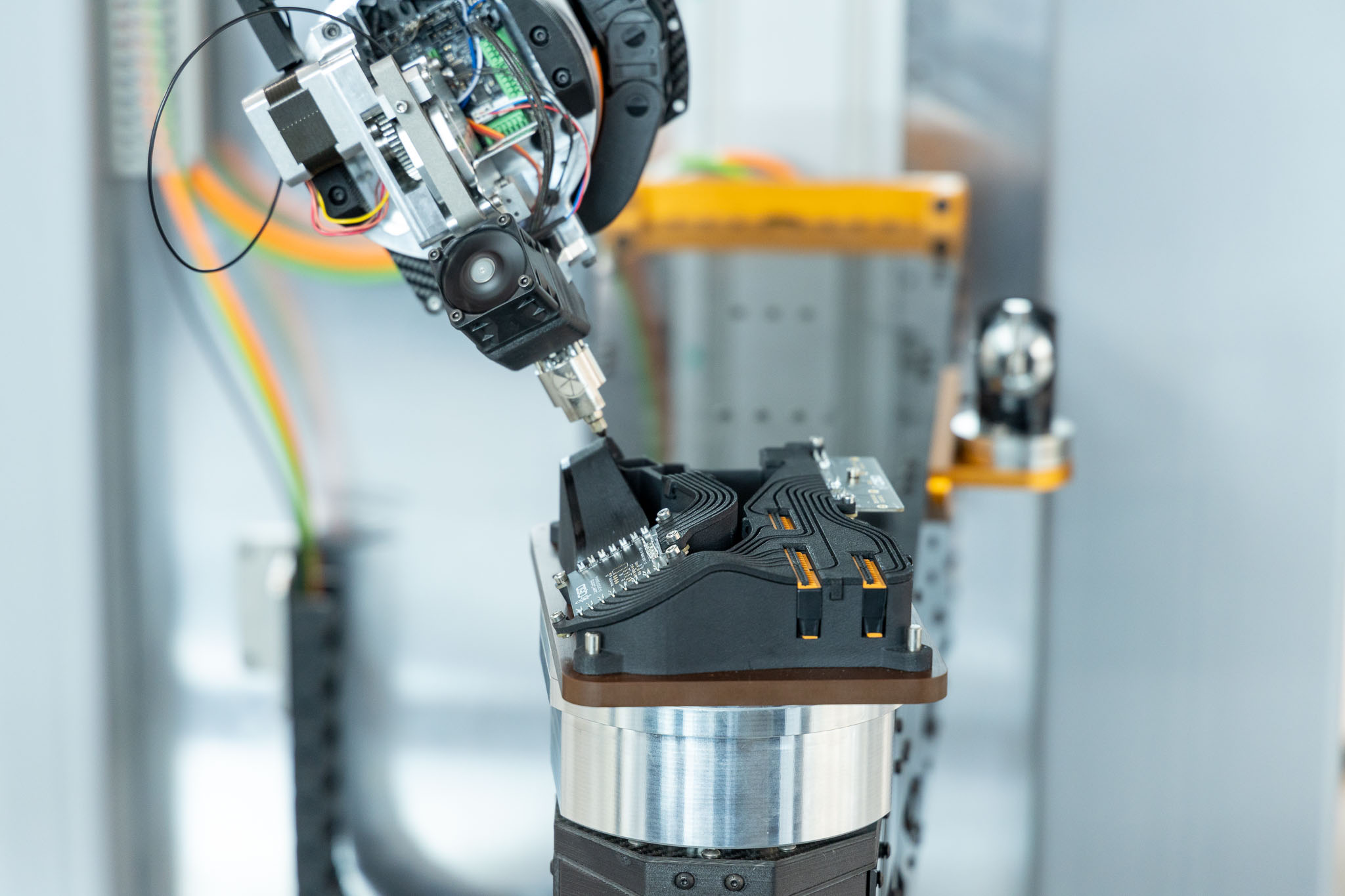

Manufacturing cell

The world’s first CAD/CAM manufacturing cell for automated production of wiring.

Our robotic manufacturing cells replace manual assembly processes by applying wires and connectors directly to the product, sub-assembly or component.

A range of deposition techniques can be deployed to add electrical functionality using interchangeable end effectors. These tools deliver:

- Insulated wire deposition

- Bare wire deposition

- Wire termination to connector

- Polymer deposition

- Printed electronics (Future Release)

- Pick and place of connectors and small components (Future Release)

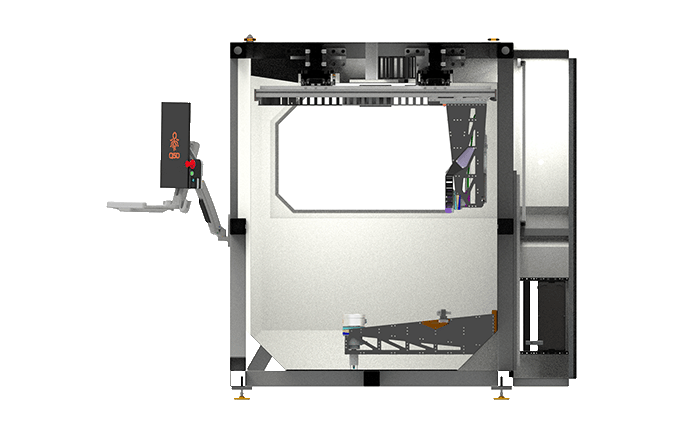

CY10 specification

The CY10 is a self-contained manufacturing cell:

- Stand alone design requires only power and internet connection

- Robust tubular steel frame for rigidity and durability

- High speed linear motors to maximise speed and productivity

- Steel and impact resistant polymer cladding for safety and environmental control

- HEPA filtration of internal environment

- Safety interlocked full width door for loading, can be configured for co-acting robot loading

- Ergonomic operator station

- Accommodates continuous supply from external material warehouse

Swipe tables

| Dimension | |

|---|---|

| Length (mm) | 2300 |

| Depth (mm) | 2200 |

| Height (mm) | 2300 |

| Weight (Kg) | 2000 |

| Robot arm maximum travel speed (mm/s) | 3000 |

Build capacity

Unlike traditional additive manufacturing systems, the CY1000 is designed to be a hybrid manufacturing system. Components or products that need electrical function can be loaded and have wires and features added to them. As a result the system will accept large parts.

The build volume describes the maximum size component that can have 5 axis manufacturing applied to it the whole volume. Larger parts can be accommodated, but some flexibility of operation is compromised.

| Dimension | |

|---|---|

| Build volume diameter (mm) | 1000 |

| Build volume height (mm) | 500 |

| Maximum weight (Kg) | 30 |

Built for production

The CY1000 is a production tool. Speed, accuracy, repeatability and the ability to work as a self-contained unit or in conjunction with other CY1000 machines and cooperative robots to create a production system.

Swipe tables

| Axis | Axis stroke | Max speed | Max acceleration | Accuracy (ideal) | Repeatibility |

|---|---|---|---|---|---|

| X | 1500 mm | 1m/s | 10m/s² | ±5µm | ±2µm |

| Y | 1050 mm | 1m/s | 10m/s² | ±5µm | ±2µm |

| Z | 750 mm | 0.5m/s | 8m/s² | ±5µm | ±2µm |

| B (head) | 240° (-110° / 140°) | 200rev/min | 200rev/min² | ±30 arc sec | ±10 arc sec |

| C (bed) | 360° Continuous Rotation CW/CCW | 200rev/min | 200rev/min² | ±10 arc sec | ±5 arc sec |

Normal operating speed for rotational axis is 70 rev/min

B and C motion motors are hollow to permit continuous material delivery to end effectors from exterior stores.

Hollow B and C motor specification:

| B Axis | C Axis | |

|---|---|---|

| Mass | < 3Kg | <12Kg |

| Diameter | 120 mm | 150mm |

| Total length | 120 mm | 150mm |

| Continuous torque | 15Nm | 100Nm |

| Hollow shaft | 15mmØ | 15mmØ |

| Positional accuracy | < 30 arc sec | < 10 arc sec |

| Repeatability | < 10 arc sec | < 5 arcsec |

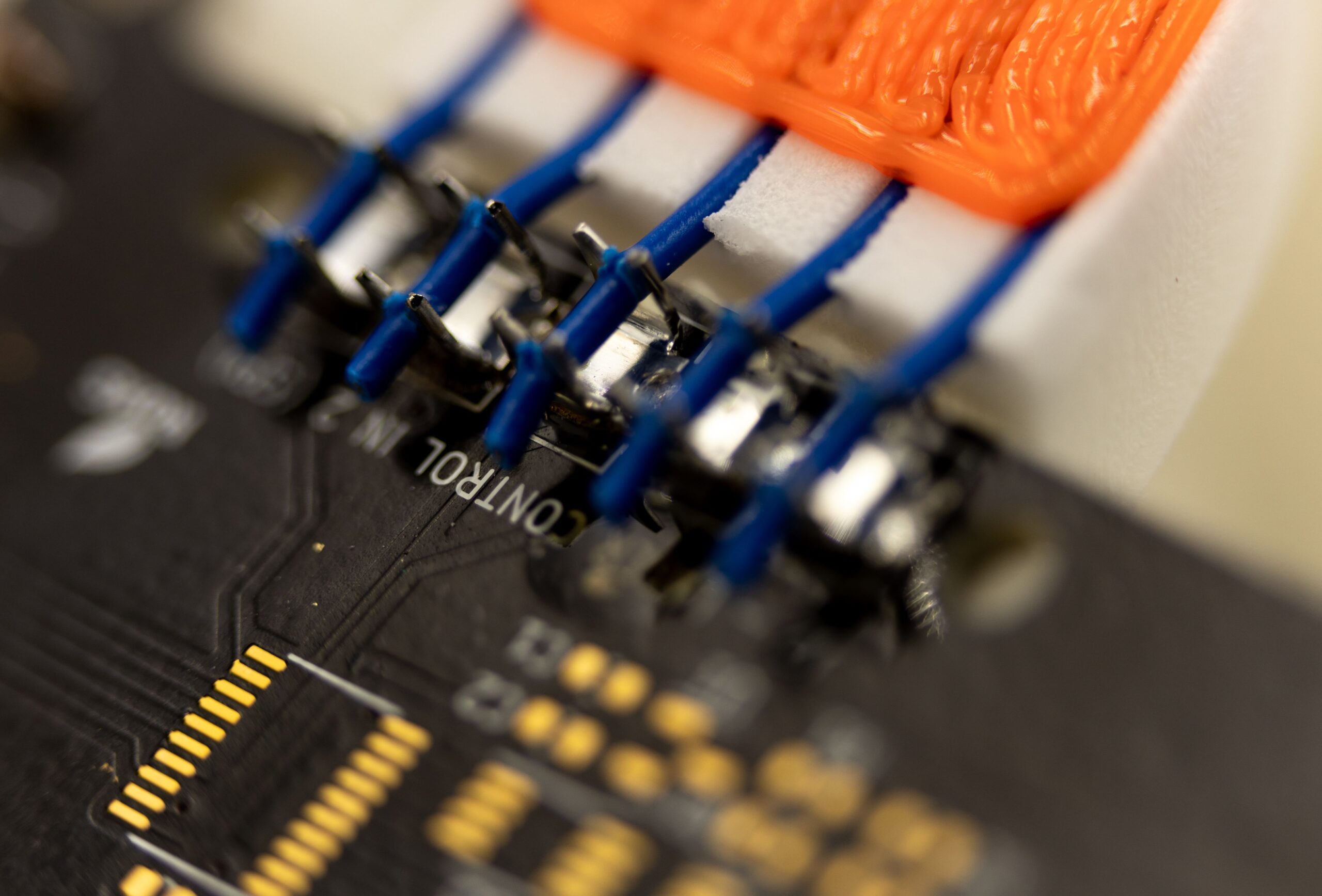

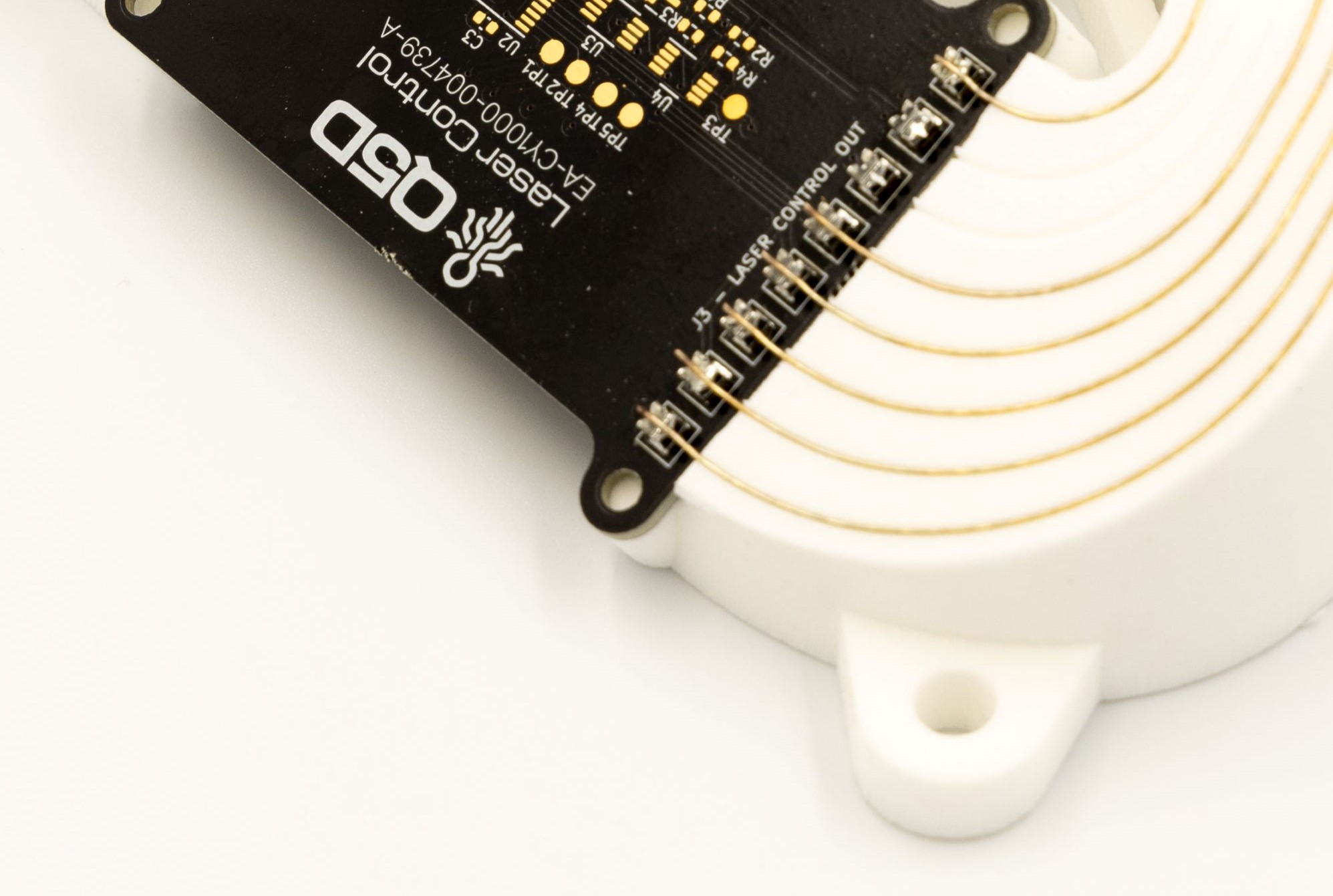

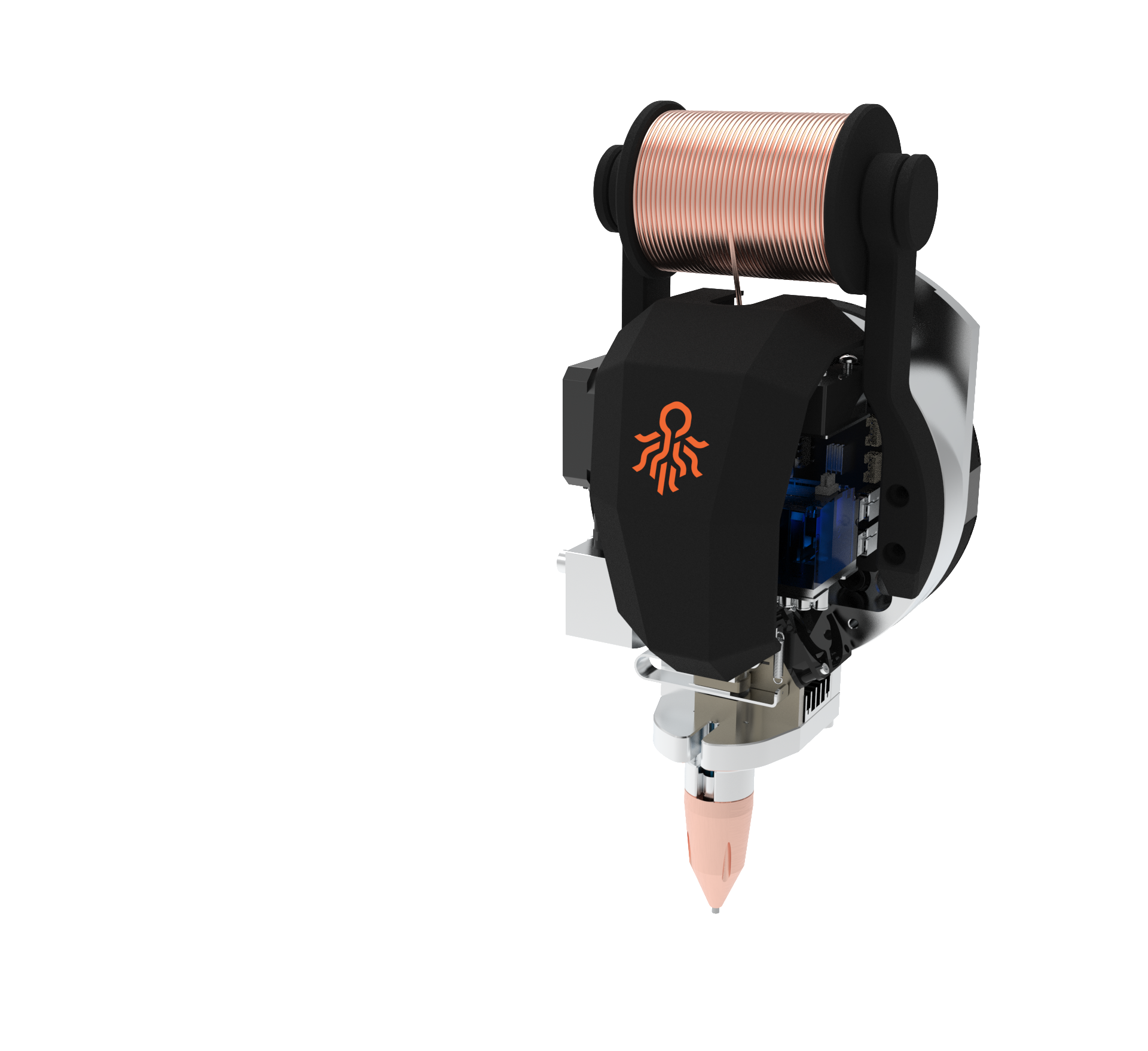

End Effectors

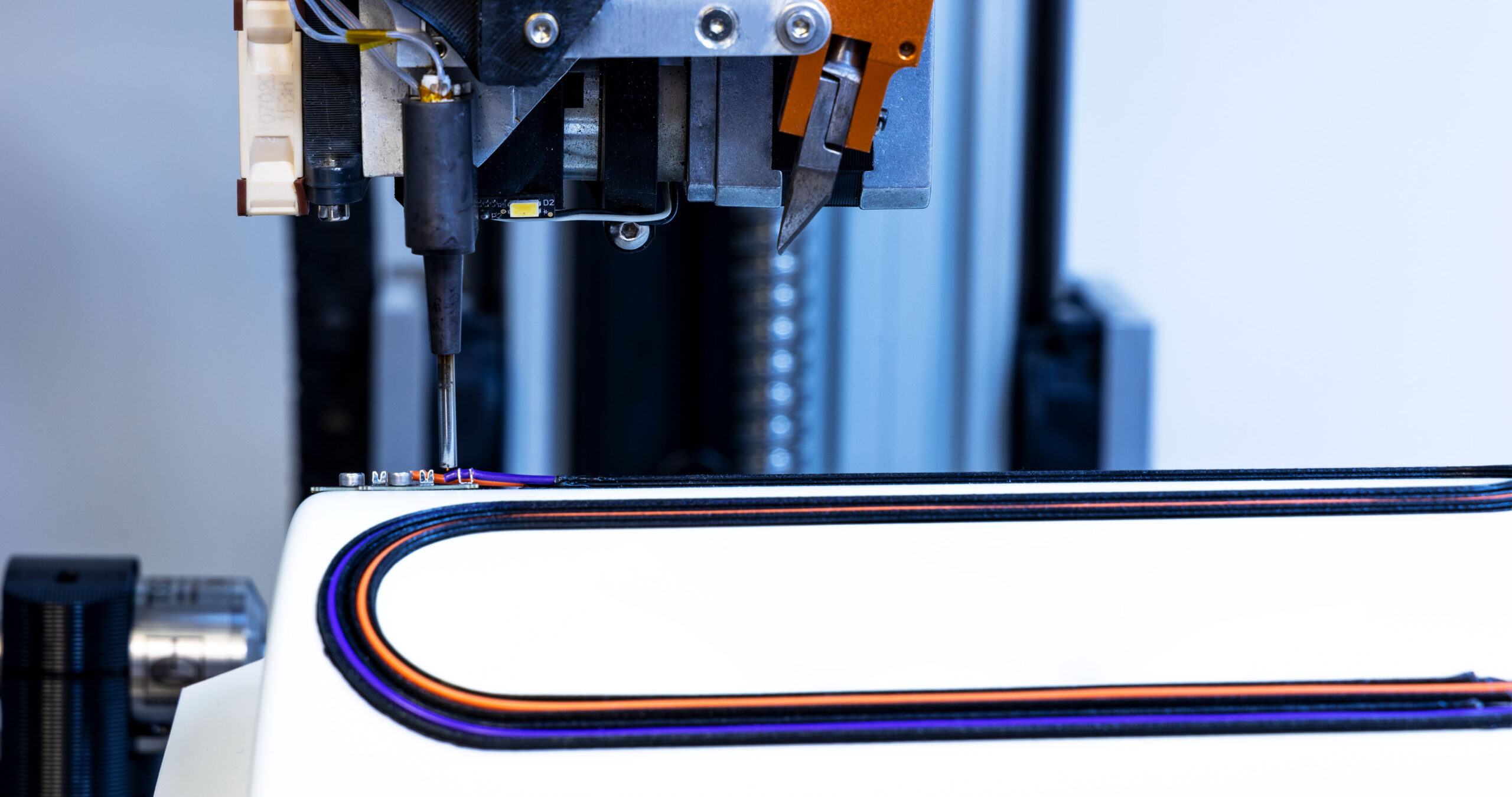

Insulated wire

Deposits insulated wire and terminates to Insulation Displacement Connector (IDC).

| Attribute | |

|---|---|

| Wire types | Most twisted or solid conductor |

| Maximum wire diameter (mm) | 3 |

| Maximum deposition speed (mm/s) | 300 |

Material supply from reel mounted on end effector (standard) or external warehouse (option).

300mm/s

Wire deposition speed

0.05mm

Repeatable accuracy

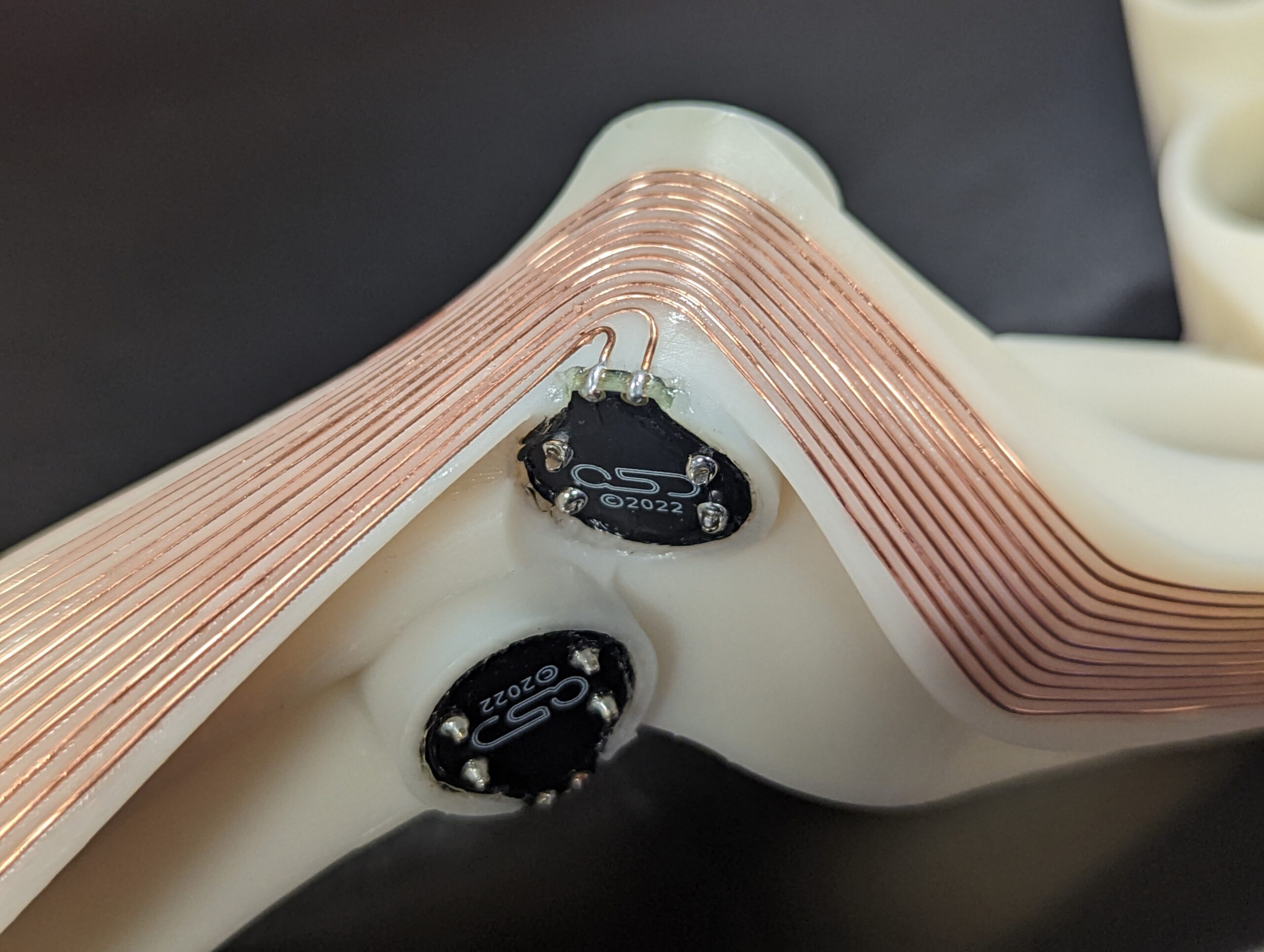

Bare wire

Deposits bare wire and terminates to Insulation Displacement Connector (IDC).

| Attribute | |

|---|---|

| Wire types | Solid conductor in Cu or Al |

| Maximum wire diameter (mm) | 3 |

| Maximum deposition speed (mm/s) | 200 |

Material supply from reel mounted on end effector (standard) or external warehouse (option).

200mm/s

Wire deposition speed

0.05mm

Repeatable accuracy

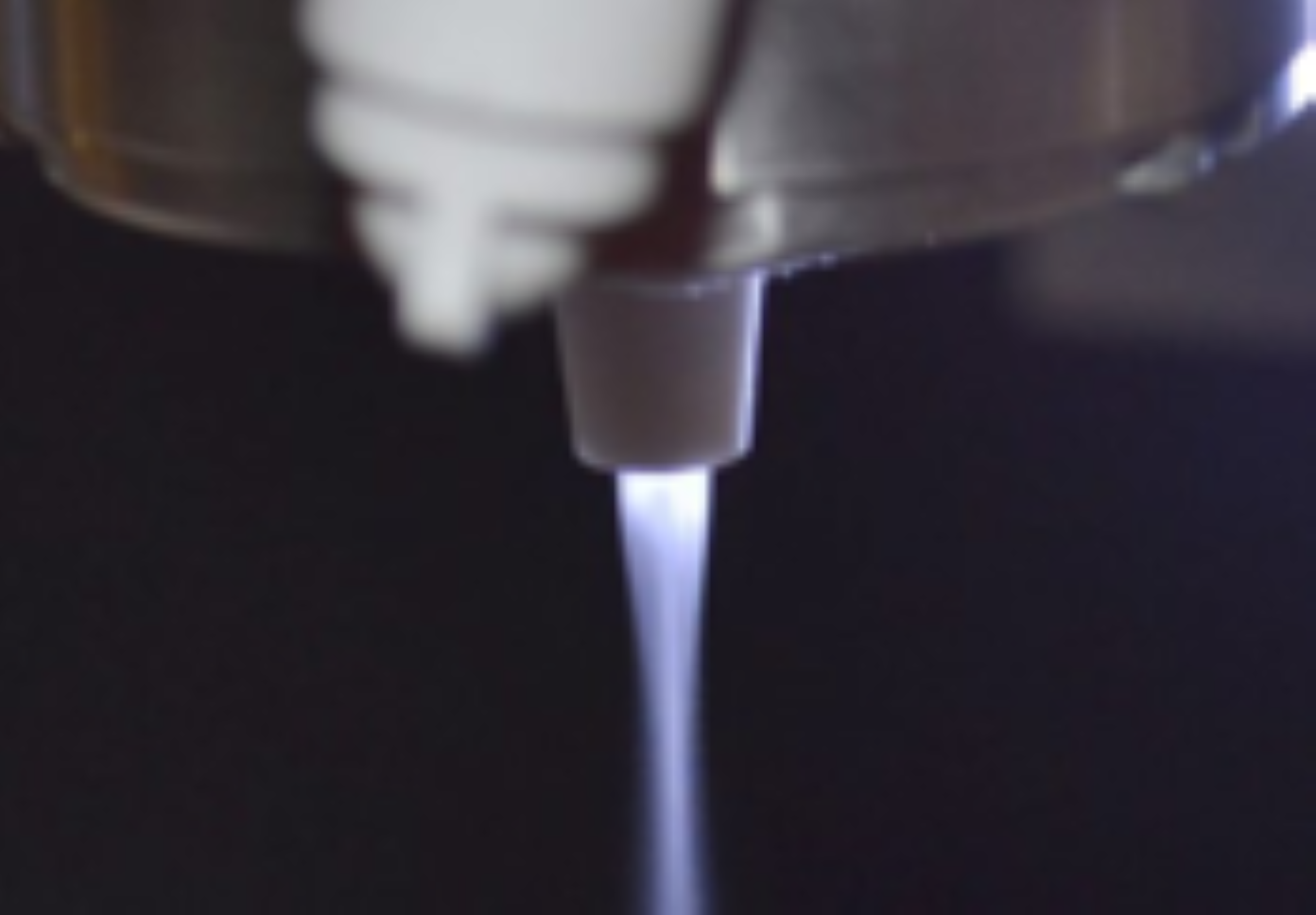

3D polymer featuring

Deposits polymer in complex 3D shapes. 5 Axis manufacturing provides flexibility in shape and eliminates most support structure needs compared to 3D printing. Used to:

- add wire traps

- over print wires to secure them

- over print connectors and bare wires for insulation

- create 3D features such as securing bosses to support variant flexibility based on a single substrate type.

| Attribute | |

|---|---|

| Polymers | ABS; PETG; Nylons; PEEK; Ultem |

| Fibre fill | Carbon or glass filled polymer |

| Single or dual material | Yes |

| Maximum deposition speed (mm/s) | 60 |

Material supply from reel mounted on end effector (standard) or external warehouse (option).

60mm/s

Polymer deposition speed

0.05mm

Repeatable accuracy

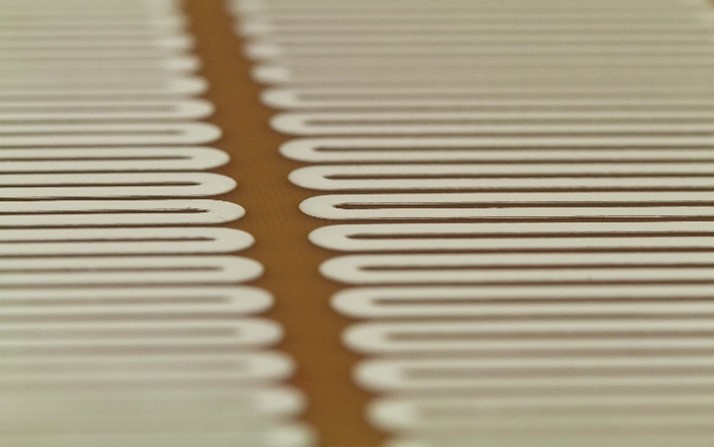

Printed electronics

Deposit conductive tracks on complex polymer or ceramic surfaces to provide power and data tracks.

| Attribute | |

|---|---|

| Conductive material | Silver or copper |

| Feature size | 150 µm gap and track |

| Feature thickness | 5 – 15 µm |

| Conductivity (typical) | 100 m Ω/ square |

Material supply from reel mounted on end effector (standard) or external warehouse (option).

150 µm

Gap and track size

5-15 µm

Feature thickness

Calibration and pick and place

Specialist end effectors are available for specific tasks, such as machine calibration and pick and place of pre-made components.