Wiring has remained stubbornly manual, creating cost, supply chain and quality issues. This is why we created Q5D.

Addressing labour shortage

Worldwide there aren’t enough skilled people to make the wiring we need.

Enabling Net Zero

As we increasingly electrify transport, industry and homes, we need more wiring.

Solving quality and logistics

A fully digital automated production drives huge savings

85% of wiring assembly processes are done by hand

As a result sourcing wire harnesses is complex and expensive. Shortage of affordable skilled labour means long and fragile supply chains with long lead times.

Automating wire harness assembly makes it possible to simplify supply chains, onshoring or insourcing production, slashing not just direct labour costs, but also inventory and transport expense.

Q5D automation also means new ways to secure wires in place, integrating them in ways that save space and weight. These new design possibilities enhance the value of the finished item for end customers.

Wiring harnesses underpin the world

Over $200 Billion is spent on wiring harness every year – and demand is rising

Automotive

A once in a lifetime shift to electric and autonomous vehicles driving greater demand.

Rapid Adoption

Large market

Technical fit

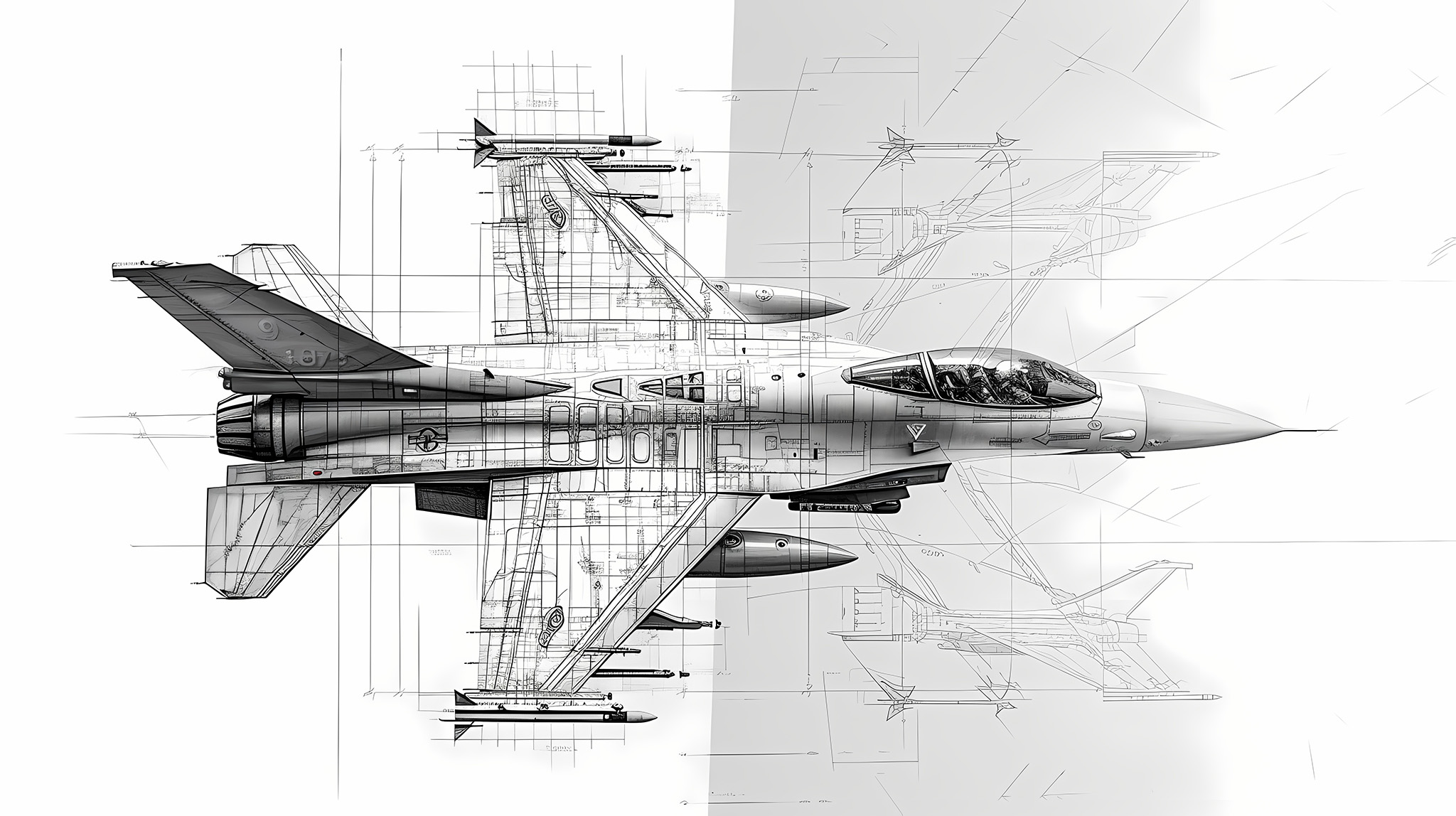

Aerospace

Technology budgets are growing, companies and governments are seeking new technologies.

Large market

Technical fit

Consumer & industrial

Industry 4.0, the Internet of Things and Net Zero targets are driving demand for wiring.