Manufacturing Cell

Our technology is developing fast and we have exciting plans. We believe Hardware as a Service (HaaS) is the best way to deliver the benefits of these developments to you.

HaaS delivers hardware, software and services necessary to deploy and support the manufacturing of your products for a monthly fee.

There are three HaaS categories of package:

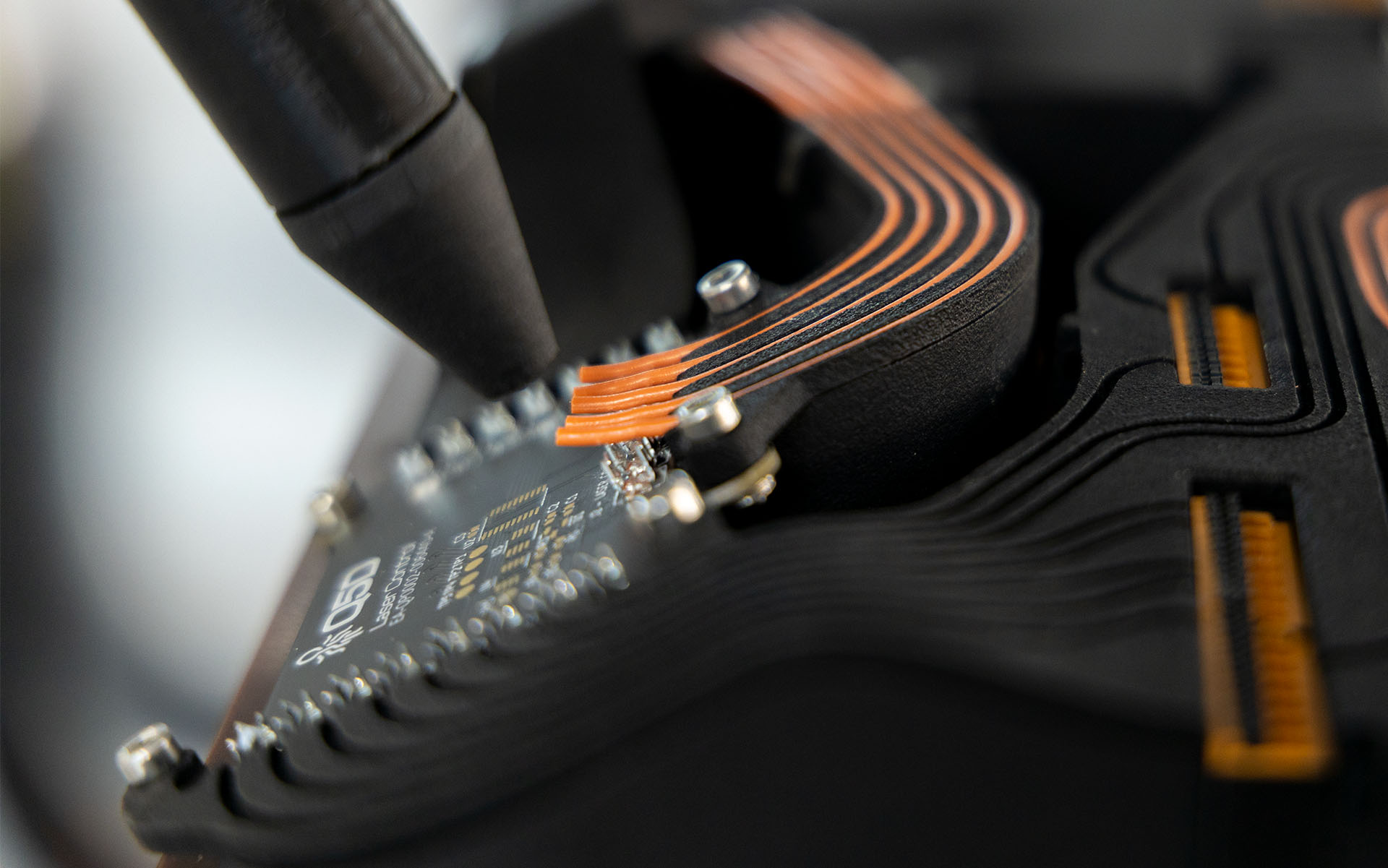

- CY10W focused on the automation of adding wires to complex products

- CY10L focused on the addition of printed circuits to non-planar surfaces

- SQ25W focused on the automation of adding wires for high volume production

Every package is tailored to your precise needs based on the elements listed below.

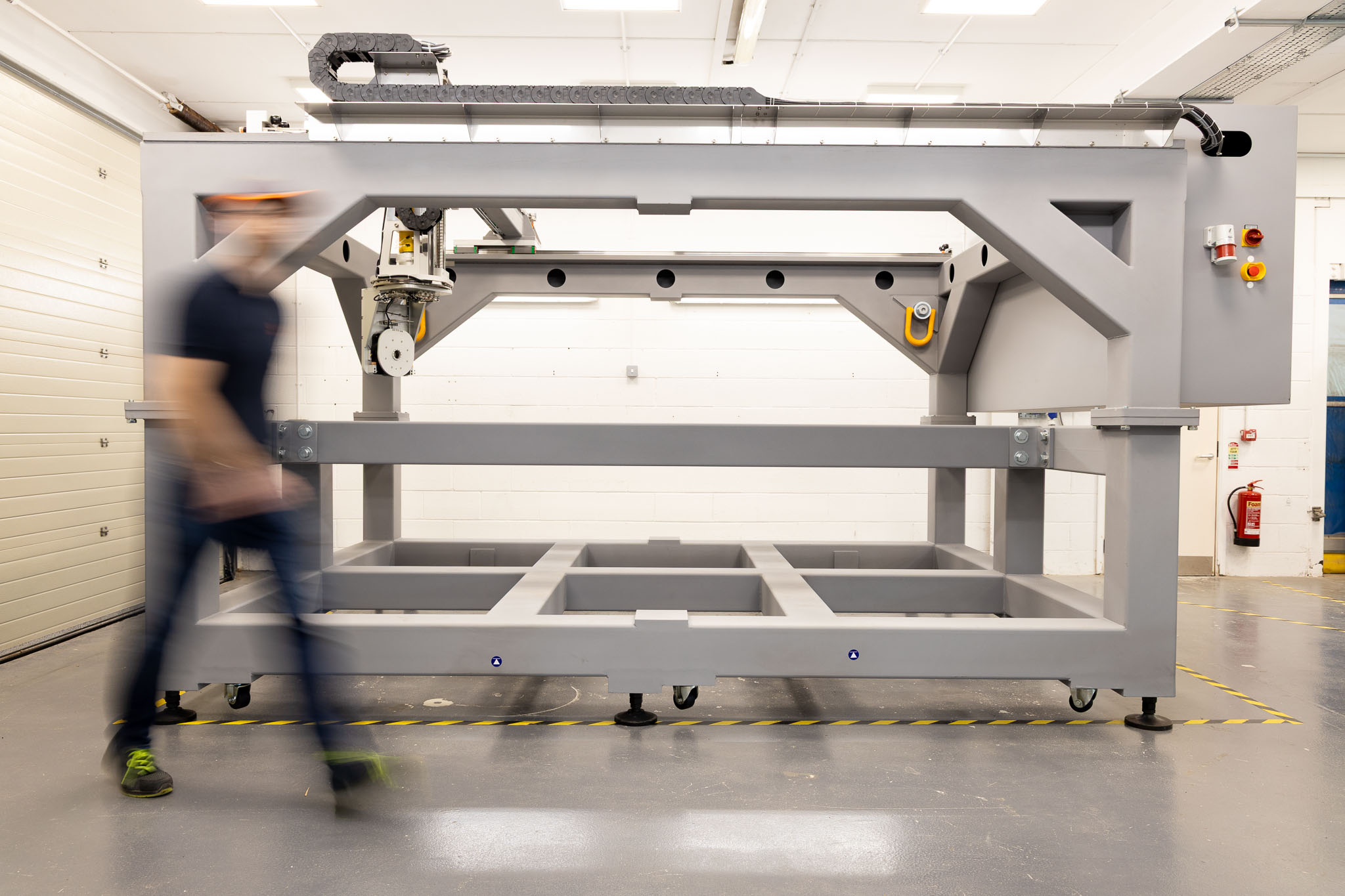

SQ25W [Release 2025]

Part design and machine control

Your designs are supported by digital twin and production tools. Our hardware as a service offer includes bespoke support packages.

Our design tools include assisted routing along surfaces to enable parametric design linked to harness data. This enables fast design iteration which can be sent directly to production.

Output from CAD is fed though CAM and processed into code which simultaneously controls each axis of the machine with smooth material feeds and precise positioning. The machine HMI is able to simulate the code to ensure expected production. This entirely digital control ensures predictable manufacturing and repeatable quality.