Case Studies

How our technologies benefit applications across various industries.

All case studies

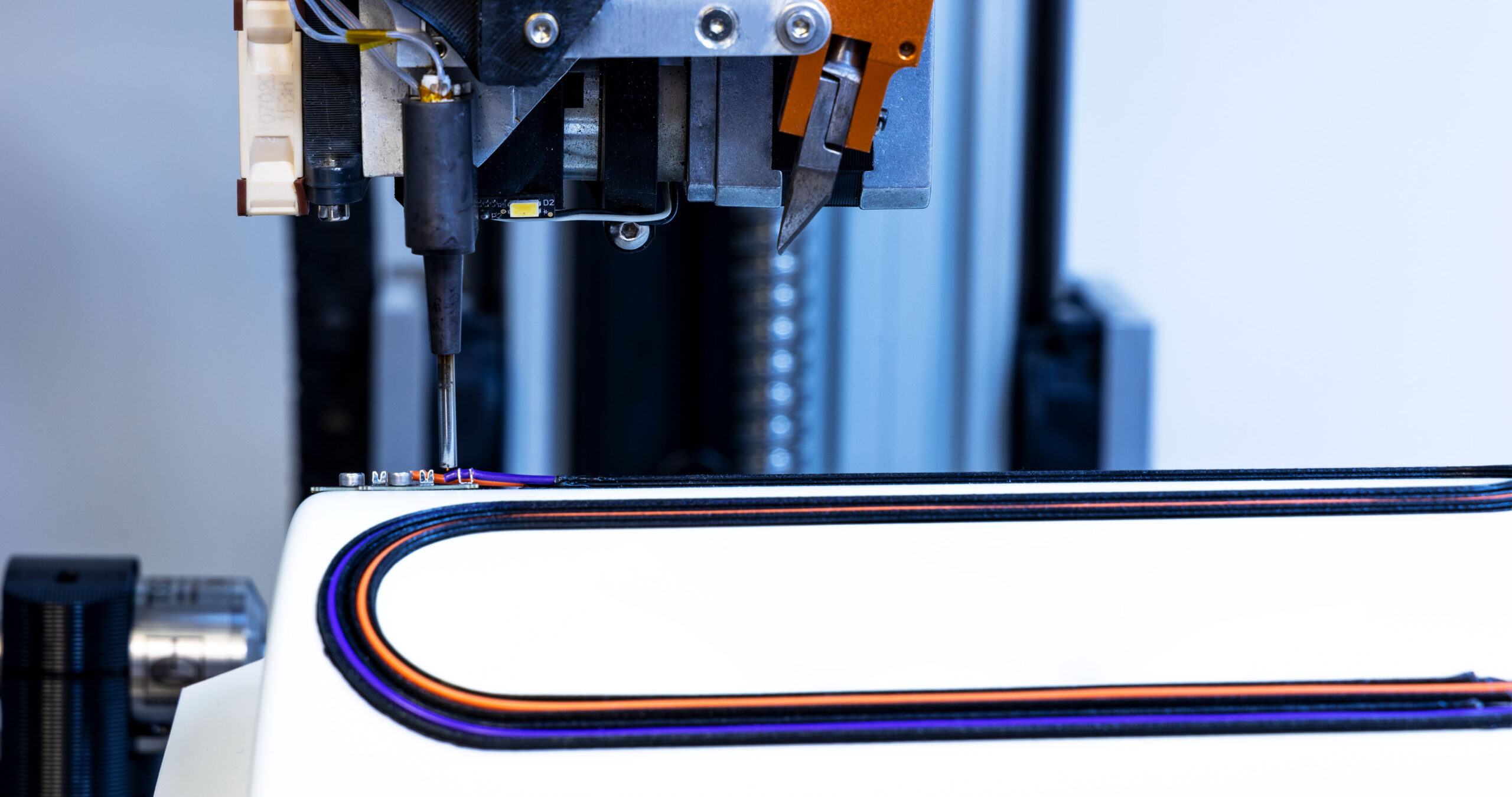

Car bumpers are a moulded shell with wiring and other devices embedded. The normal manufacturing process involves clipping a separate wiring harness to the inside of the shell to connect the lighting and sensors. This project was a concept study carried out to assessed the feasibility of producing car bumpers complete with wiring automatically.

Q5D has the only process capability that can work at large scale on aerospace components. Frequency selective shielding has [...]

Manufacturing seats and cabin interiors for commercial aircraft is highly labour intensive. The range of customisation required from airline [...]

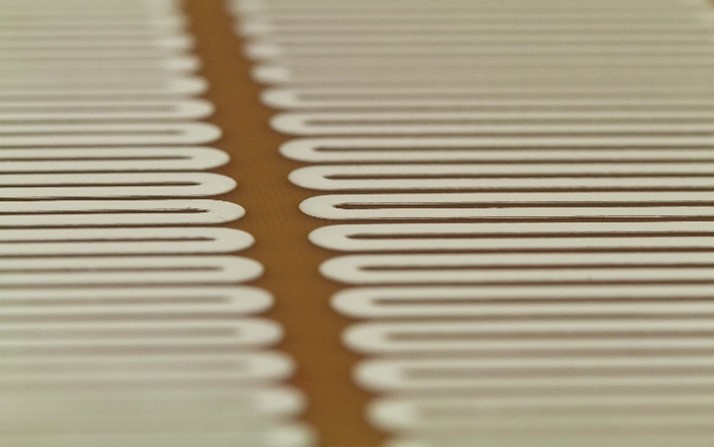

This aerospace customer wanted to investigate methods to create heating tracks on complex composite surfaces. Many aircraft surfaces need [...]

Enabling robotic assembly of the final product is one of the key advantages of Q5D's approach. With our machines [...]

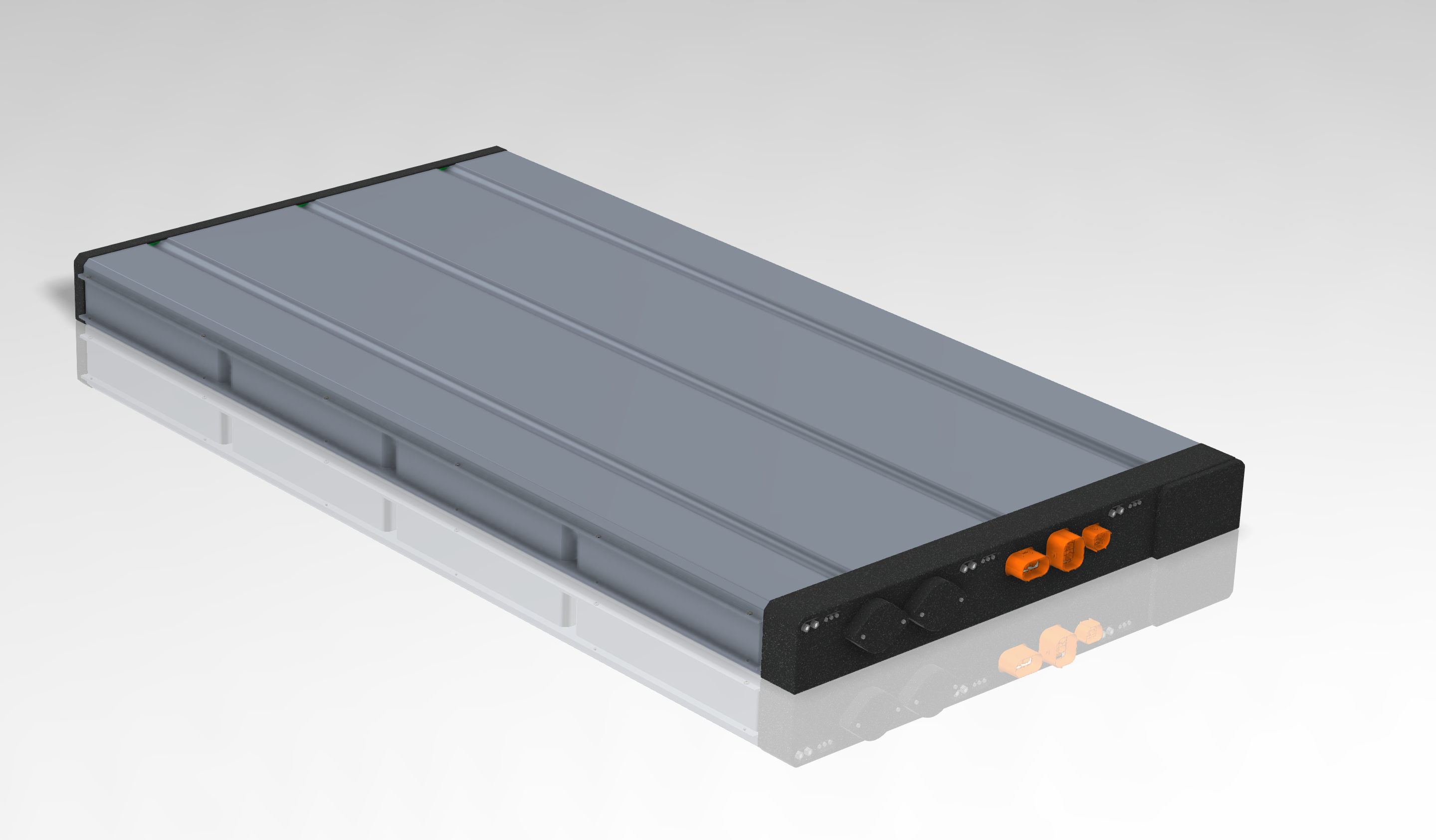

Near Field Communication of all kinds needs an antenna. In this instance the customer was seeking a way of [...]